VW’s US Innovation Hub simply introduced 4 breakthroughs in electrical mobility and sustainable transport – right here’s what the analysis heart has achieved.

Volkswagen’s Innovation Hub opened in 2020 on the College of Tennessee (UT) Analysis Park at Cherokee Farm in Knoxville. The federally funded Oakridge Nationwide Laboratory (ORNL) is there too. VW collaborates with UT and ORNL scientists on its EV analysis. Right here’s what the VW Innovation Hub has been as much as:

AI-optimized EV battery pack body

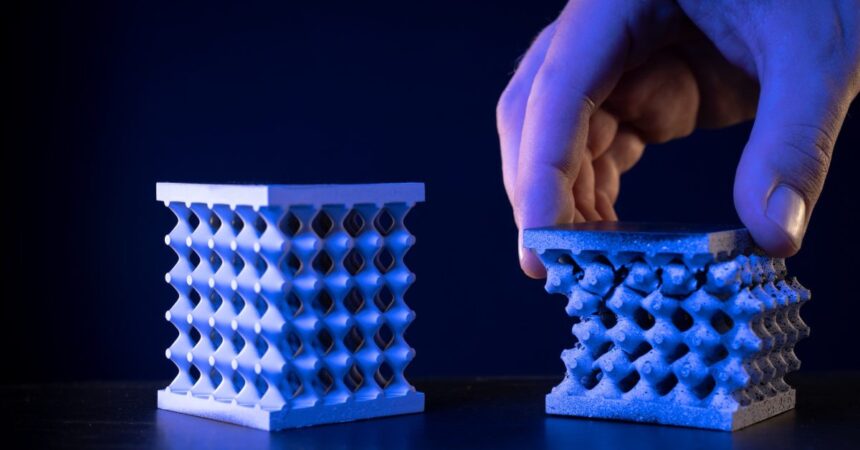

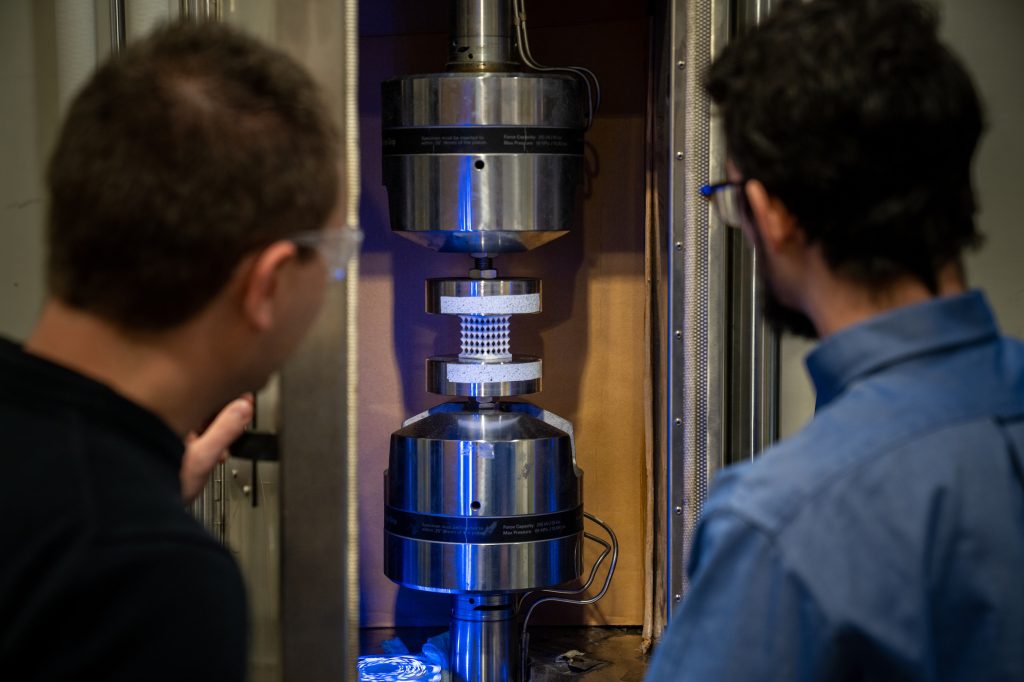

Volkswagen researchers are engaged on new materials buildings to cut back car weight, which in flip helps to extend the vary of EVs. The goal of the primary pilot is to interchange the metal body that homes the EV battery pack with one thing lighter.

The staff used synthetic intelligence (AI) with tens of millions of parameters on UT’s high-performance laptop cluster to develop a modular repeating construction within the form of tiny pyramids (fundamental picture). The construction could be 3D-printed from liquid resins and might maintain 30K occasions its personal 0.15 lb weight (68g). So this body could be as much as 60% lighter than the metal body. The researchers discovered that the resin body absorbs extra power than the metal body (they’re testing its sturdiness within the picture above), which implies it’s sturdy.

Electrek’s Take: Intriguing. As VW is claiming that its resin body is lighter and stronger – and we’re going to imagine it’s made sustainably – I hope to see this progress past the pilot stage and can control it.

EV interiors product of paper

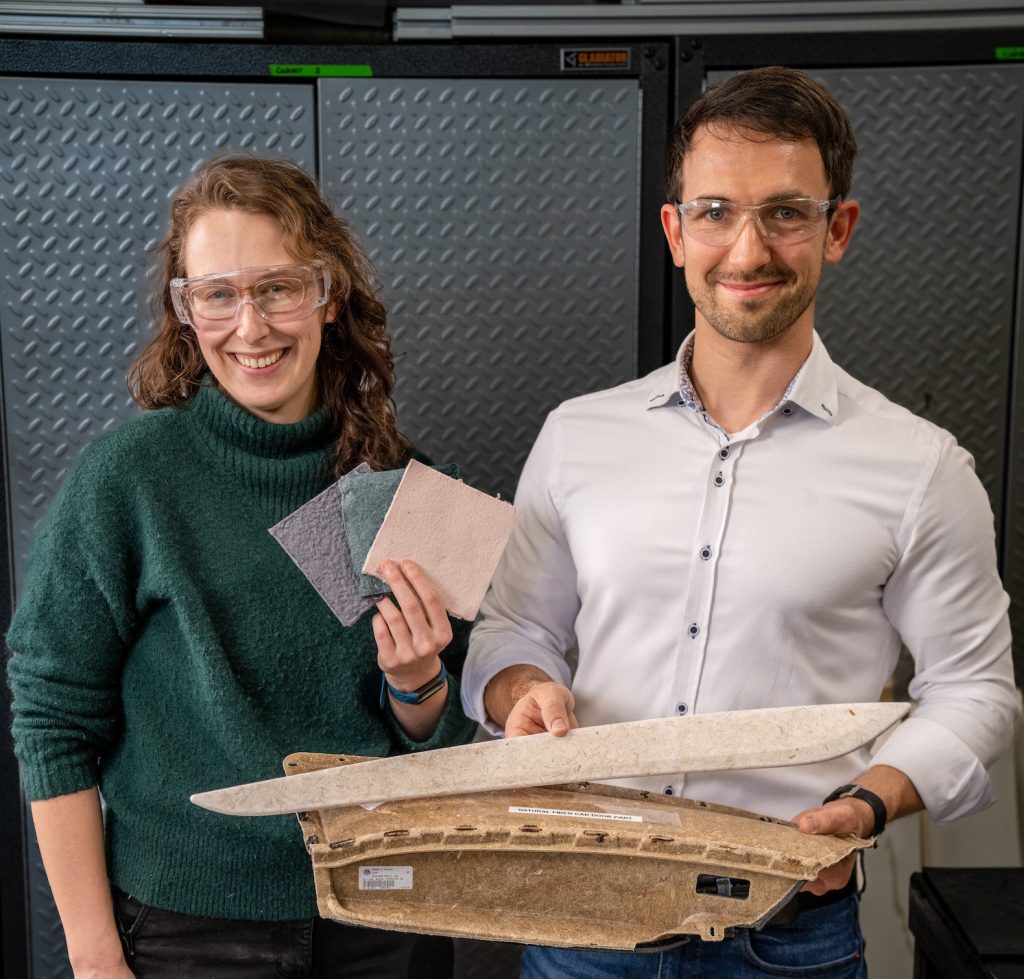

Scientists at UT’s Middle for Renewable Carbon are utilizing paper as a recyclable different to plastic elements and foils for EV interiors. The staff has patented a way of preforming and hot-pressing cellulose fiber-reinforced thermoplastics into sturdy inside elements.

The recyclable paper-based composites could be reworked into numerous inside styles and sizes, and completely different textures and colours could be added.

VW says it’s “checking alternatives” to incorporate paper-based inside elements in future fashions and “work to help industry-scale manufacturing.”

Electrek’s Take: Any transfer towards recyclable supplies and away from plastics can’t come quick sufficient. No timeline is given right here from VW on industry-scale manufacturing plans; it’d be nice to see this materials utilized by VW in mass-produced EVs.

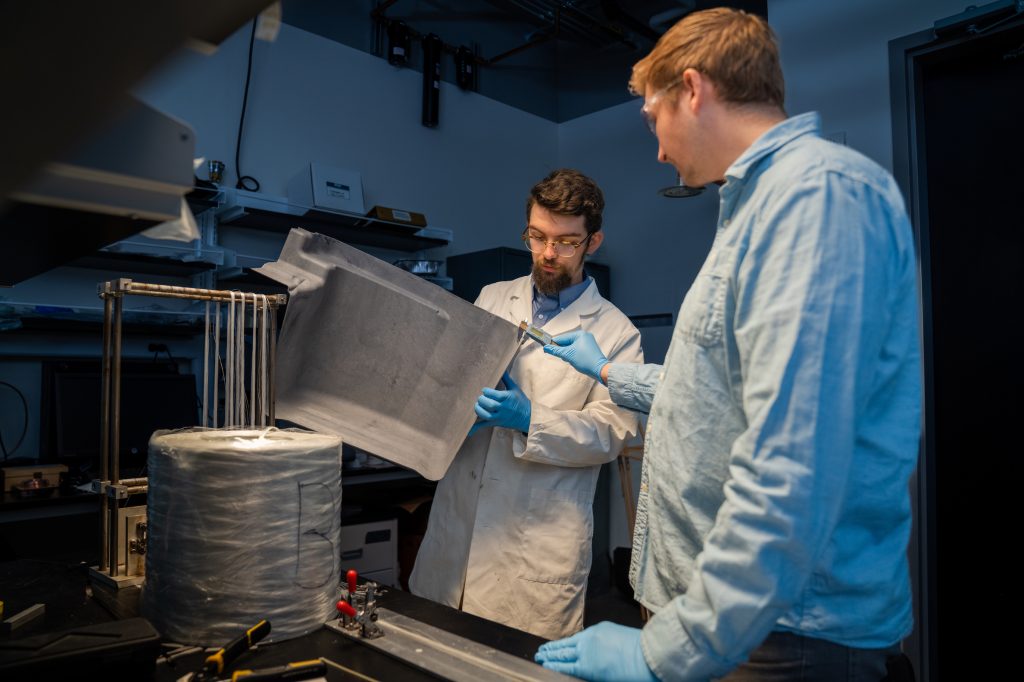

Light-weight fiber composite physique elements

Researchers re-created the liftgate of a 2020 Volkswagen Atlas utilizing sheet molding compound, a kind of fiberglass-reinforced plastic. The brand new liftgate was 13 kilos lighter than the steel one, leading to a weight financial savings of greater than 35%. That will assist enhance the vary of EVs.

VW says that the fiber composite liftgate doesn’t want adjustments in meeting sequence in comparison with steel liftgates, so the previous could be produced in excessive volumes.

Researchers have lately additional refined molding processes and methods to optimize sturdiness, high quality, and design choices.

Electrek’s Take: Fiber composite physique elements are already in manufacturing at Bentley and Lamborghini, that are a part of the Volkswagen Group. They’re utilizing the brand new supplies and the molding course of for the Bentley Continental and the Lamborghini Aventador. These are luxurious automobiles, so it’s not precisely mass manufacturing, however researchers are additionally exploring fiber composite pickup truck beds and different elements.

Wi-fi EV quick charging

VW’s staff has patented a coil and charging pad design with silicon-carbide supplies. In early trials, the automaker says that the prototype silicon-carbide inverter system has confirmed to be extremely environment friendly. The analysis staff has been capable of enhance the charging energy stage as much as 120 kW with this prototype from an earlier 6.6 kW prototype, and their objective is to achieve 300 kW.

Electrek’s Take: There’s no additional elaboration from VW on what’s subsequent for its wi-fi EV quick charging venture, so I’m guessing that is nonetheless in early phases. It’d really want numerous finessing to be viable on a widespread scale. Nonetheless, to progress from 6.6 kW to 120 kW is an achievement. It’d be good to simply pull up over a charging pad in a parking spot and begin charging, particularly when it’s extraordinarily scorching – that’s you down south – or when it merely received’t cease raining, like us up right here within the Northeast.

I hope no less than half of those tasks go into mass manufacturing and change into cost-effective. However seeing how VW has carried out a short-term spending freeze, it’s in all probability not going to occur quickly.

Photographs: Volkswagen

In the event you’re an electrical car proprietor, cost up your automotive at residence with rooftop photo voltaic panels. To be sure you discover a trusted, dependable photo voltaic installer close to you that provides aggressive pricing on photo voltaic, take a look at EnergySage, a free service that makes it simple so that you can go photo voltaic. They’ve lots of of pre-vetted photo voltaic installers competing for your enterprise, guaranteeing you get top quality options and save 20-30% in comparison with going it alone. Plus, it’s free to make use of and also you received’t get gross sales calls till you choose an installer and share your cellphone quantity with them.

Your personalised photo voltaic quotes are simple to match on-line and also you’ll get entry to unbiased Power Advisers that will help you each step of the best way. Get began right here. –advert*