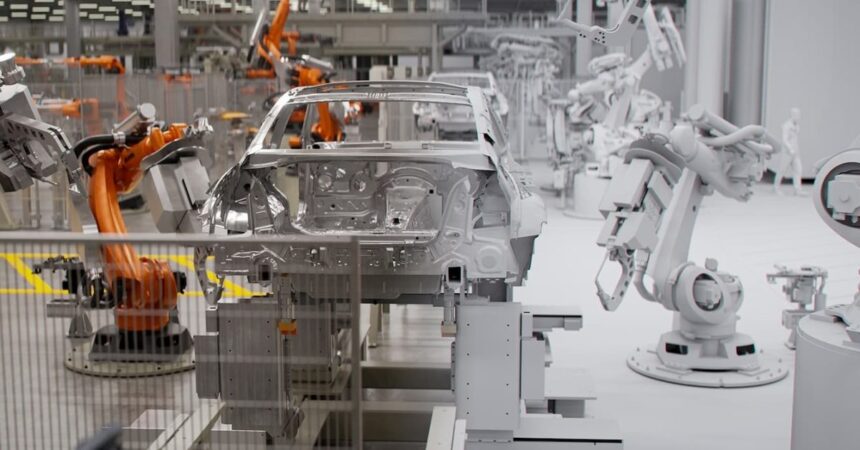

BMW has begun producing its next-generation all-electric Neue Klasse models, accelerating production by at least two years ahead of the scheduled rollout of the entire lineup. NVIDIA’s cutting-edge digital computing platform enabled BMW to debut the globe’s initial fully digital publication within the NVIDIA Omniverse, supporting its innovative Neue Klasse EVs.

BMW leverages NVIDIA Omniverse to spearhead its next-generation electric vehicle (EV) initiative?

The NVIDIA Omniverse platform approximates the true world’s complexity, leveraging AI capabilities to facilitate the creation and operation of virtual reality experiences in the metaverse.

NVIDIA’s unparalleled expertise enables the creation of photorealistic, large-scale simulations that bring innovative concepts to life in a revolutionary way – also known as digital twins.

BMW is further leveraging the power of NVIDIA Omniverse at the Gamescom Trade Conference (GTC) to revolutionize its manufacturing ecosystem, including its dedicated EV plant in Debrecen, Hungary?

Although construction on the new facility hasn’t started yet, with the first vehicles not expected until 2025, BMW is already producing virtual vehicles at its metaverse-based plant. The capability to monitor the functionality of abilities in near-real-time ensures a seamless and eco-friendly onboarding process.

Milan Nedeljkovic, the head of manufacturing at BMW, notes:

With NVIDIA’s technology and artificial intelligence, we are able to set up new factories at a significantly faster pace and operate them with unprecedented efficiency. This initiative ultimately leads to significant financial benefits for our organization.

According to Nedeljković, the foundation for successful innovation lies in meticulous planning, which is now being revolutionized by advancements in virtualization and artificial intelligence, allowing BMW to streamline and enhance its strategic planning processes. The platform enables seamless collaboration among BMW’s global teams, fostering expedited decision-making and enhanced productivity through real-time interactions.

BMW and NVIDIA have conducted a tour of their joint manufacturing facility, highlighting the efficiency and potential of integrating artificial intelligence into electric vehicle production through the Omniverse platform. Test it out under.

As part of their joint demonstration, BMW’s global planning team collaborates with Nedeljković and Jensen Huang, NVIDIA’s CEO and co-founder, on a virtual planning exercise to optimize the design of a new body shop at one of their manufacturing facilities.

Following the introduction of a novel manufacturing concept, the team works together to refine the approach, utilizing real-time visualization to bring the process to life as they collectively develop a solution.

Upon identifying the optimal placement for the robotic system, the workforce may initiate a simulation to visualize the component’s functionality as a replacement and ensure seamless operation.

BMW’s digital planning visionaries have crafted a comprehensive “masterplan for the automotive manufacturing of tomorrow,” aptly named BMW iFACTORY, revolutionizing the company’s approach to production. BMW introduced its manufacturing strategy last year, shifting focus towards digitalization, sustainability, and environmentally conscious initiatives.

BMW’s Hungarian factory is slated to commence operations in 2025, marking a significant milestone as it prepares to manufacture the company’s inaugural next-generation Neue Klasse electric vehicles (EVs) and embark on a new era of innovation.