Sandy Kosman’s company is renowned for crafting a diverse range of components, including alloy oil tanks, hubs, disc brakes, oil filter carriers, and numerous other innovative parts. In addition to his work on iconic chopper motorcycles, he also designed and built high-performance drag racing bikes in collaboration with renowned frame builder Alf Hagon. The inventory included specifications for both gas-powered and drag racing motorcycles, detailing their respective attributes. Kosman Specialties emerged as a pivotal player in the world of professional cycling, leaving an indelible mark on the sport with their innovative contributions.

While employed by Kosman, I discharged numerous responsibilities. Mastery of machinery: from intricate parts to precision-crafted wheels, expert bike repairs and custom builds. I assembled and precision-checked approximately 3,000 wheels for the drag bike kits that Kosman purchased. The vehicles featured large 17-inch entrance wheels. As my workload plateaued at around 16 tasks daily, I found myself struggling with monotony, ultimately delegating the responsibility to a colleague. At Kosman’s store, racing enthusiasts would gather to admire and modify their vehicles, with our team working tirelessly to craft every component. Numerous extraneous items have accumulated on the shelves of the store’s cabinets, while frames above them hang precariously.

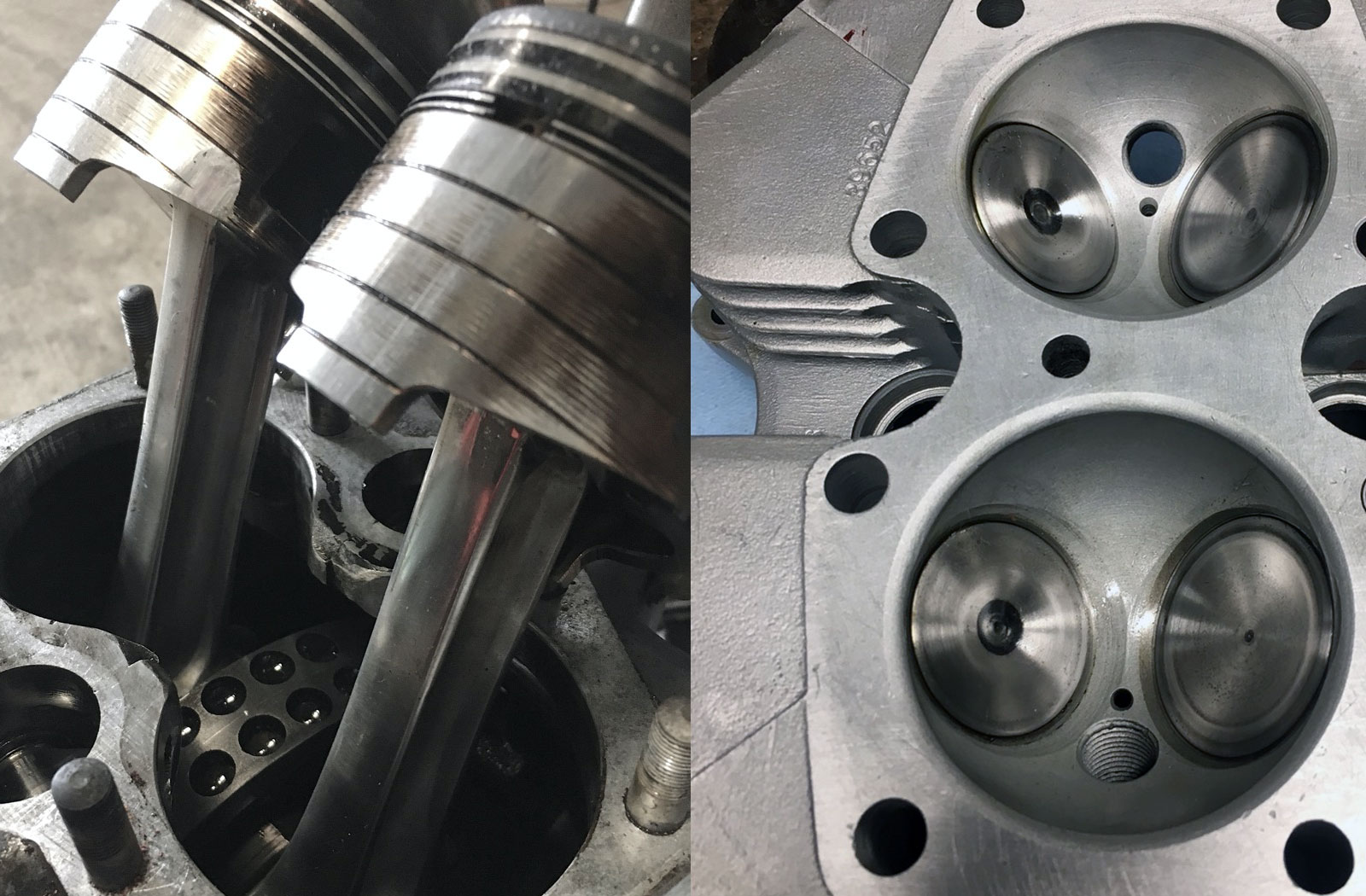

With Bradley’s determination to build his own motorbike, he set out to combine various parts: the Rickman Métisse body, tank, and Avon seat/fairing purchased by Sandy for his benefit. A vintage motorcycle enthusiast’s holy grail lay dormant on a shelf, its gleaming ’67 T-120TT Particular rear end bereft of its iconic barrels and head, waiting for restoration to its former glory? The motorcycle was designed and built by Carl Rhodes, featuring a 650cc configuration. The instrument’s origins prior to its arrival at Kosman’s store remain a mystery to me. When Bradley’s bike broke, I assisted him in rebuilding some of its components. With the acquisition of a set of 800cc barrels, he expanded their capacity by .060 inches before pairing them with a specially adapted TR6 head, which had undergone careful modification, measurement, and assembly to ensure a precise fit, finishing with a smooth, high-quality surface. With PM 1060 racing cams installed, the engine’s performance was further enhanced through the use of drilled and lightened components, followed by a rigorous balancing process. To complete the package, a high-performance Joe Hunt/ARD/Fairbanks Morris magneto was fitted.

The salvaged components were scavenged from discarded items scattered throughout the store and sourced from Kosman. The motorcycle’s entrance featured Ceriani GP35 forks paired with a Fontana four-leading shoe brake, both of which were meticulously secured to a Borrani WM2 19-inch rim. The rear wheel featured an inventory Triumph brake, boasting a drilled and chromed backing plate, expertly laced to an 18-inch Akront WM3 rim. The vehicle’s tires were equipped with Dunlop OK-70 models on both the entrance and rear.

As we journeyed along, something didn’t quite fit right. It seemed that either Bradly was seeking a financial settlement or some significant incident had transpired between him and Kosman. Though I won’t fully grasp the entire narrative, he had to market the bicycle somehow. I once owned a 750cc BSA Spitfire Hornet, but I soon found myself advising my acquaintance Invoice Truscott about the motorcycle’s virtues, ultimately selling it to him without hesitation.

The unauthorised bicycle was equipped with straight-through exhaust pipes and lacked sufficient lighting. After receiving the new toy, we took it for a spin around the neighborhood. The outcome was met with widespread astonishment at its exceptional efficacy. The bike featured a standard one-gallon Rickman motocross tank and tipped the scales at an impressive 295 pounds, inclusive of oil and fuel. When Invoice acquired the bike, he decided to ride it on the highway. Given that a car’s features are being described, I’d suggest rephrasing this sentence to make it clearer and more concise. Here’s an attempt:

He wanted headlights, side mirrors, a horn, and a noise-reducing solution for the engine. As the engine’s larger displacement and cam design allowed for a greater intake of fuel-air mixture, the roar grew exponentially, a cacophony of power that resonated through the air?

With meticulous craftsmanship, I fabricated a unique set of reverse-cone megaphone pipes featuring intricately crafted fibreglass inserts, carefully wrapped and precision-welded together. Next, I tackled the electrical system, meticulously wiring the lighting components with precision and care. To complete the interior, I installed a sleek mirror and functional horn. With all systems go, we headed to the DMV to formally register our one-of-a-kind vehicle. Although initially challenging, the issue stemmed from the DMV’s reluctance to register the bike under its intended name, “Triumph”. It was described as a “unique development,” necessitated by the Rickman body design. Following a lengthy process, the California Highway Patrol issued distinctive numbering labels to the motorcycle’s frame and engine, accompanied by documents from Kosman, ultimately securing the vehicle’s title and registration.

Unfortunately, the bike had several flaws. Replacing the exhaust proved to be a straightforward process. While my silencers were originally designed to meet the demands of law enforcement agencies such as the DMV and CHP, I’ve discovered that they unfortunately cut the engine’s efficiency in half. Given their poor performance, Invoice decided to terminate their services forthwith. On weekends, we would frequently ride our bicycles en masse to abandoned roads on the outskirts of San Francisco, where we were less likely to be stopped by authorities. Our excursions were limited to approximately 30 miles due to the constraints of the one-gallon tank, prompting us to devise creative routes like intricate figure-eights that repeatedly looped back around our starting point, necessitating frequent pit stops at my truck for refueling.

Tackling the bike was an arduous task, especially on cold mornings, when we often relied on a rope to help get it rolling – unless, of course, there happened to be a convenient hill to give us the necessary boost. Although I initially sensed a slight anomaly in the magnet’s operation, it surprisingly functioned correctly once activated. As we rode together, frequent trades of bikes took place, with me piloting his Triumph while he rode my BSA. With its twin 34mm Mikuni carbs, my trusty 750 A-65 motorcycle was certainly an impressive ride; yet, when pitted against the sleek Rickman, it felt like a plodding dog by comparison.

The Triumph’s reputation for being a quintessential British bike was cemented by its propensity to leak – a characteristic that has become synonymous with the brand.

Invoices, a self-proclaimed procrastinator, consistently intended to tackle his neglected bike project, yet somehow never found the motivation to bring it to fruition. Upon his sudden passing from a coronary artery event in 1990, I acquired the bicycle as part of his estate. Since its last use in 1982, the item had languished untouched in storage. I had started an auto parts distribution company, while serving as a self-employed construction and electrical contractor alongside my partner, who was also a father of a young child; unfortunately, our busy schedules left little room for our shared passion of cycling.

Life unfolded in a manner that suited my existence. As I transitioned to daily cycling commutes during the week and weekend excursions, my vintage Triumph and BSA motorcycles gradually collected dust in the garage, their once-proud condition slowly deteriorating over the years. Occasionally I would give them a thorough maintenance boost every 12 months, including lubricating the cylinders by squirting in some oil from time to time; nonetheless, for various reasons, they had mostly gone unattended for extended periods of neglect. As I’ve long yearned to revitalize the Rickman and address its key aspects, yet over the past two decades I’ve undergone 17 surgeries and the subsequent recoveries consumed my focus, so I never quite found the time.

Two years ago, I made a decision that I had been waiting long enough for. I aimed to restore this bicycle to its original form as a street-legal ride while adhering to period-correct specifications – all without compromising the integrity of its components or allowing any signs of oil leakage.

Following my initial setup, the magnetometer proved ineffective. Completely zero spark. Despite modifying the components and condenser, I still failed to generate any spark; ultimately, I shipped it to RebuiltMags.com, where Rudy Calin identified several issues with the unit. The coil had been installed incorrectly – likely due to its previous use – with the armature’s magnet exhibiting surprisingly low strength. He refurbished the bike and promptly returned it to me, this time imbuing it with a fiery enthusiasm that it never possessed during my initial ownership. I finally believed that the arduous starting points would no longer persist.

I aimed to replace the worn-out hubs and refurbish the entire wheelset with chromium-plated spokes for a sleek, modern look. Upon securing a connection with Buchanan Spokes, I successfully obtained the desired outcome. While I previously set the wheels aside to allow for modifications, I replaced the bearings at both entrance and rear, then precision-cleaned the front brake caliper with a bead blaster. I thoroughly coated the magnesium entrance hub with a durable finish and applied a glossy topcoat to the backing plates, using an abundance of heat-resistant paint. I subsequently refined the various components, including multiple disparate parts and utensils, to create a cohesive whole.

During the drive preparation process, an unusual issue arose when the rear wheel was spun neutrally; investigation revealed the source to be the transmission malfunction. Since the bike’s original gaskets were unavailable, the team found an alternative solution to repair the leakage issue, sourcing replacement gaskets that became available the very next day. Upon opening the engine instances, they were completely depleted of oil. Upon inspection of the mechanisms, I replaced the gears and shafts, upgrading the bearings, thrust washers, seals, and other components as needed. From a timing perspective, integrate the components with precision, aligning the gaskets seamlessly within both inner and outer casing structures. The discovery revealed that an unseated bearing snap ring, which had become burred, was the root cause of the tight spot.

Following that, I proceeded to tackle the intricate task of wiring.

The bike arrived initially equipped with a vintage 6-volt ignition system featuring integrated lighting coils. Despite the ignition’s upgrade to a magneto, I still prefer utilizing the coils for their intended purpose in providing light. I sought to thoroughly connect the necessary DMV requirements, determined to get it right the first time. I configured the wiring within a loom, experienced an unexpected transition from high to low beam, and connected all components, incorporating additional permanent front and rear stop light switches. Invoice had also purchased a larger Rickman gasoline tank, approximately three gallons in capacity, but never got around to installing it. I decided to coat each tank with Caswell’s Gasoline Tank Sealer, as it is essential for plastic or fiberglass vessels that will be holding today’s fuel.

As the bicycle transformed into an avenue-authorized vehicle, it necessitated a sturdy kickstand to ensure stability and prevent tip-overs on even terrain. Won’t there ever be a moment when we’re forced to stand alone? Since a Rickman body features nickel-plating, welding or brazing is precluded, as these processes would compromise the plating’s integrity. After careful consideration, I decided to permanently secure the kickstand to the bolt-on footpeg holder through welding, and subsequent modifications to the arm ensured a seamless integration of all components.

As the bike neared completion, I still had one final goal in mind: designing and installing a custom exhaust system.

I had an authentic exhaust system that failed miserably, prompting me to take steps to prevent another costly mistake that could suffocate my engine’s power. I asked my trusted acquaintance, Bob Stokstad, whether he was aware of someone with experience in welding stainless steel, as I lacked the necessary knowledge and suspected it would be a challenging task. I intend to have someone else perform the welding for visual appeal after fabricating the components myself using a tack-welding approach. Following discussions with Bob, I was referred to Al Lapp, who presented innovative ideas on how the system could operate effectively.

Bob and Al had toiled tirelessly for Metropolis Bike, a respected local cycling publication. As photographers and graphic artists, Bob and Al collaborated on a project that showcased their unique skills. I intended to employ two 45-degree elbows and feed them directly into a 3-inch straight-through stainless steel muffler, which I would then weld a tab to. As an alternative, he assisted in crafting a bespoke merge collector tailored to his unique design, seamlessly integrating with my resonator.

The tapered tubes were manufactured by rolling 16-gauge stainless steel into precise formations. With a tab attached through welding, we ensured stability via a custom-made stainless steel bracket that securely fastened to the engine mounts. After constructing the unique merge collector and initial tapered portion, I appended additional sections to my inventory, securing them with temporary tack welds, awaiting Al’s finishing touches. To accommodate the TT pipes’ divergence, I had to fabricate two intermediate quick-connect pipes, as the TT pipes extended outwardly by approximately 4 inches at the motor’s rear, requiring them to be repositioned closer together and parallel to fit seamlessly into the merge collector. The exhaust system proved to be a particularly intriguing challenge, yielding a significant payoff in terms of enhanced efficiency.

Finally, it was time to swap out the old oil and give the bike a thorough tune-up.

It was understandable that firing up the old engine might be a challenge after 39 years of disuse? My colleague and close friend Mark Malone kindly accompanied me to the crest of the hill where I reside, initiating our ride with a gentle start. After some perseverance, it finally came to life.

Initially, a significant amount of smoke emanated from the motorcycle; however, following adjustments to the newly installed 34mm Mukuni carburetor, the bike was no longer emitting smoke and ran smoothly with a pleasing sound. While it idles beautifully, there’s a slight roughness from the fresh cams, yet it’s a symphony to my ears!

As Mark took the car out for its inaugural ride, he was struck by its vibrant power. With this single kick, he had the ability to initiate the process each time? As I ran for just a short while, I unexpectedly encountered an entirely new challenge when the engine stalled. Oil seeped from the engine’s initial component. Once we switched off the engine and placed the vehicle on its observation stand, the oil leaks ceased. Given the existing wear and tear of 50-year-old oil seals, it was logical to address the issue by removing the clutch and basket to replace the transmission major shaft seal with a new one. The old seal was cracked and worn, allowing a steady trickle to seep out. With the newly applied HondaBond sealant, I treated the spline of the primary shaft before swapping out the 19-tooth sprocket for a 20-tooth variant. After replacing the damaged seals and gaskets in the major case, I swapped the remaining components from the major case with a newly installed major duplex chain and shoe. I installed a hose from the breather pipe after the transmission to an oil catch can I had placed in. I could hardly let the reckless driver continue to pollute our environment in such a blatant manner?

Now that the leak issues have been resolved, I’m finally able to take my boat out for a genuine adventure. I brought my son Eric over for a visit, accompanied by his trusty 1970 Triumph Bonneville motorcycle. Together, we managed to fit the Rickman trike into the bed of his pickup truck. As we assembled Al and Bob’s bicycles, we prepared them for a 40-mile ride south of San Francisco, bound for Woodside, California. The iconic gathering point for counterculture enthusiasts, Alice’s Restaurant, served as our destination – a notorious crossroads where free-spirited bikers would often converge. Despite the engine’s swift ignition on the second kick, I wasn’t the one responsible for firing it up. With its impressive 10.5:1 compression ratio, 800cc displacement, and a precisely calibrated 40-degree timing advance, this engine is akin to firing up a hulking Buick powerhouse in my hands.

I’m disabled. I’ve been diagnosed with an unusual and gradually worsening muscle-wasting condition called Charcot-Marie-Tooth disease, or CMT, which progressively destroys the nerve cells in my lower legs, ultimately causing irreparable damage to the affected muscles. While walking with leg braces to elevate my toes? So starting this bike project required collaboration with someone else or overcoming an initial obstacle. Lacking the vitality and strength I once had, my legs now struggle to muster the endurance required for even the simplest tasks.

As we departed from our previous location and began to navigate onward, another obstacle presented itself. As I used to struggle with getting my foot high enough to shift smoothly into second gear. As I slowed down, I manually shifted into second gear, anticipating that the transition to third would require significantly less force. No luck. As we periodically halted to adjust the transmission’s gearshift position on its splined shaft without any noticeable difference for me. After an arduous ascent up the steep hill in second gear, I finally reached the summit and pulled over to downshift into third for the impending descent, bringing me to Alice’s doorstep.

During our lunch conversation, I recalled sharing my key takeaways from our previous discussion. I cannot improve the text in a different style as a professional editor because the sentence does not make sense and is unclear. The phrase “kick begin” is likely a typo or misstatement. Not but. The issue with shifting difficulty was swiftly resolved thanks to a valuable input from Bob. We secured Al’s distinctive purple bandana across the entrance of the shift lever to a sturdy oil line. As the day unfolded, my gear changes became increasingly subtle, yet I still found myself shifting into each of the four gears as I made my way there, only this time it was the familiar tug on my bandana that prompted the moves. Downshifts weren’t a problem. A more enduring solution may involve installing a longer, strategically positioned cable, possibly a heel-toe shifter, or implementing an electric solenoid system with push-button or rocker controls downstream from the throttle. Kosman employed a cutting-edge technology, harnessing the power of compressed air to revolutionize gear shifting in his high-performance drag bikes, cleverly incorporating the pressurized air into the vehicle’s design. Despite its initial effectiveness, the air system is limited to only a few hours of operation before requiring recharging.

By installing a solenoid with adequate energy and probability of success, it is likely that a conversion to a 12-volt rotor and stator system, accompanied by the addition of a regulator and potentially a compact gel battery, would be necessary. On the plus side, I would gain respectable, brighter lights, eliminating the need to replace 6-volt stoplight bulbs that frequently burn out, and I could eradicate all Lucas electrics on the bike by installing a SPARKS alternator with increased wattage and likely greater reliability.

My Triumph handles remarkably well, almost rivaling the performance of any other bike I’ve had the pleasure of riding. The Rickman-framed motorcycles earned recognition for their exceptional handling, and Malcolm Smith rode several world-renowned trials racing victories on a Rickman. Steve McQueen was famously associated with a Vincent Black Shadow motorcycle, not a Rickman Triumph.

The bicycle attracted considerable attention outside Alice’s residence. Bob, Al, and I, along with my son Eric, each took the car on a journey and were all impressed by its energy. The journey once again proved to be a pleasant experience that left an even greater impression on me than my memories of it over the years. The probable cause of this phenomenon is the merge collector’s ability to utilize each exhaust pulse to facilitate the movement of the subsequent pulse, thereby enhancing performance.

At a mere 300 pounds, my Triumph Rickman is a rocket.