Combine the pinnacle-performing engine from the Triumph modern classic range with a framework deeply respected in motorcycling lore, effectively merging two icons to create something truly extraordinary? What do you get? A contemporary-day Triton cafe racer. A motorcycle build of exceptional quality and craftsmanship, poised to conclude a legendary ride. Behold, Neil at Made in Metallic Bikes in Stafford, UK, has successfully achieved this very outcome.

With seven years of experience crafting bespoke bicycles in his modest home-based workshop, Neil has honed his skills as a solo artisan. He’s a skilled metalworker who prefers traditional techniques, utilizing tools like sandbags, hammers, and English wheels to shape his creations. He consistently employs the same approach in both his motorcycle builds and cafe racers.

In recent years, a enthusiast approached Neil with an ambitious idea: to build a Norton Dominator. After a brief conversation or two with Neil, who desired to customize his ride just that little bit more, he acquired a sleek and modern Triton cafe racer. It sufficed to say that the shopper required minimal encouragement, and the transaction progressed seamlessly.

The Triton, a legendary cafe racer, was born from the union of a Triumph and a Norton’s distinct characteristics, giving rise to its iconic status among motorcycle enthusiasts. Consequently, the moniker “Tri-Ton” signifies a union of Triumph and Norton. In the early 1950s, Triumph’s engines dominated the market, but despite their superior power output, the company struggled to deliver a comparable handling experience. Norton’s legendary “featherbed” frame, renowned in its era for its exceptional agility through corners. While younger, performance-driven Brits sought a perfect blend of technology and heritage, the collaboration between Norton and Triumph seemed as unlikely as two stubborn rivals sharing a bed. As a result, enthusiasts started integrating Triumph engines with Norton frames, giving rise to the iconic Triton cafe racer.

Neil drew inspiration from vintage cafe racer history books and incorporated them into his modern Triton build. He began by selecting a cutting-edge engine from the archives – specifically a 9-month old Triumph Thruxton 1200. He retrieved a vintage 1958 Norton Featherbed frame from the depths of his well-stocked workshop. Their union was truly divine.

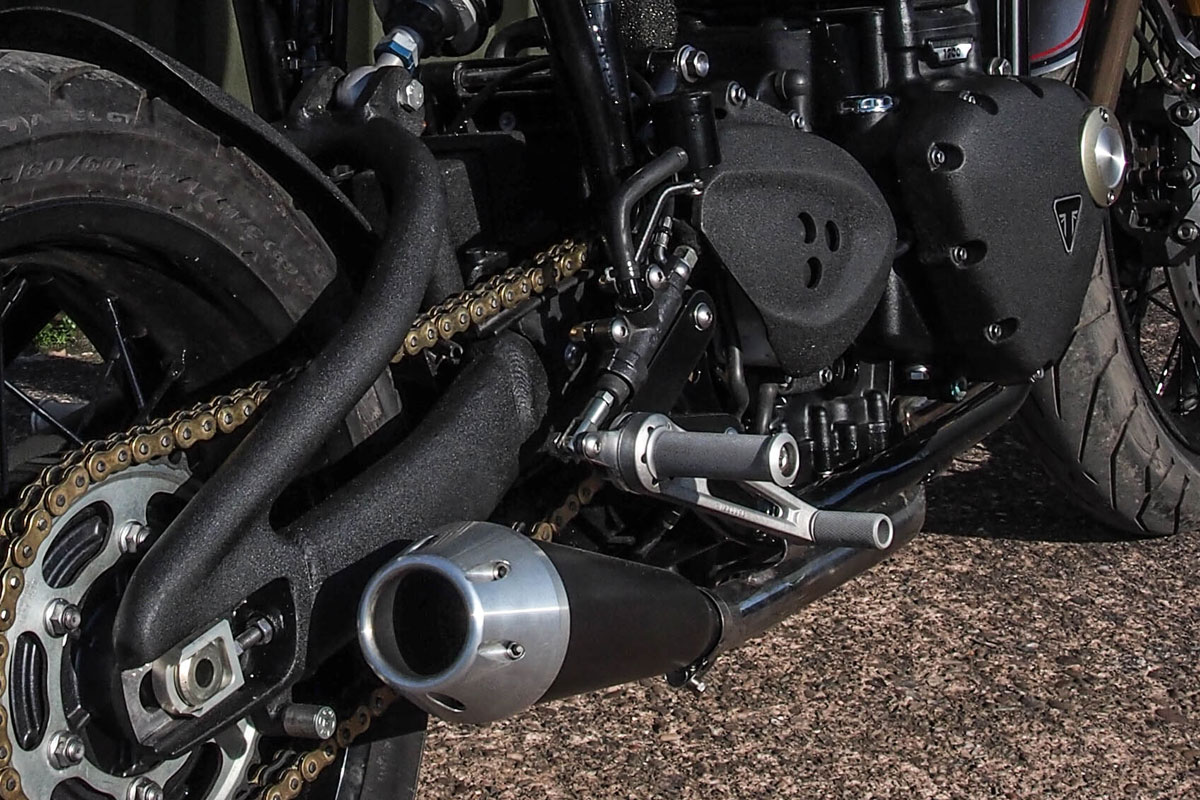

Two primary components of the construct were separated by a 60-year interval. To ensure the featherbed’s durability in the face of the enhanced energy unit’s forces, Neil implemented several key modifications. Upon completion of the project, the engine was carefully positioned and secured using custom-made MIM (metal injection molding) engine mounts designed to provide a precise fit. As the engine roared to life, he focused on liberating 1,200 cubic centimeters of Hinckley’s potent power through a custom-designed chrome steel exhaust system, culminating in precision-crafted reverse cone mufflers that perfectly harmonized sound and performance. In keeping with the cafe racer ethos, attention subsequently shifted to enhancing the bike’s suspension and braking systems. Upgrades that are truly transformative in nature. The Öhlins entrance forks and corresponding monoshock have been borrowed from an Aprilia RSV, following minor modifications to the bike’s chassis and swingarm.

Neil carefully shaped the alloy sheet into a precise silhouette of the bike, meticulously removing excess material from the tank, seat unit, entrance, and rear guards to achieve a flawless outline. While he characterizes this phase as the most challenging aspect of the construction process, I concur that his execution was nothing short of flawless. The standard entrance package includes a suite of aftermarket accessories: clip-ons, switchgear, grips, and mirrors.

The brake light is seamlessly integrated into the seat unit to create a sleek finish, while all lighting features are powered by energy-efficient LED technology, reflecting the bike’s commitment to modernity, reliability, and eco-friendliness? A subtle dash of wrinkle-coat black wraps the swingarm, engine covers, and sprocket cowl, introducing a tactile element to an otherwise sleek finish. Neil opted for a classic Norton-inspired colour palette on the tank, tail, and guards, combining silver/gray hues with black and crimson pinstripes, and a unique take on the Triton emblem that reflected his personal style.

As a result, there may potentially exist an expanded inventory of discarded items alongside the already established list of problems. The catalytic converter was dismantled along with the air intake housing and the anti-lock braking system components. This simplification enabled the wiring loom to undergo a significant streamlining. With its lightweight alloy bodywork and array of thoughtful design elements, this special Triton boasts an impressive 61kg weight reduction compared to a standard Thruxton 1200, further enhancing its overall agility and handling prowess. The undeniable boost in energy-to-weight ratio has undoubtedly left a lasting smile on the faces of its proud owners. The Triton’s sleek hull touts slender dimensions and breathtaking aesthetic appeal. We extend our sincerest admiration to Neil of Made in Metallic Bikes for crafting a truly exceptional café racer that epitomizes style and sophistication.

MADE IN METAL MOTORCYCLES

Story by Ben Pilatti