In a remarkable coincidence, French father-son duo Michel and Jimmy Messina pursue parallel careers while sharing a passion for classic motorcycles and hot rods. In 2019, Jimmy’s life took a dramatic turn when he stumbled upon information that upended his reality, given his expertise as both a mechanical engineer and a seasoned race mechanic. The revelation had the potential to crush expectations and consume individuals with anxiety. Jimmy refused to merely accept the circumstances; instead, with his father’s steadfast support, he chose to surpass his limitations and craft a truly unique, bespoke bicycle.

“Three years ago, my son Jimmy was diagnosed with lung cancer, forcing him to stop working,” says Michel. Initially, my aim was to undertake a unique father-son project by integrating a Harley-Davidson engine into a Voxan vehicle’s chassis. With the body acquired and a Buell S1 engine in hand, I took the next step. Despite the obstacles, Jimmy proposed building an entirely new chassis from the ground up.

As concepts oscillated between refinement and revision, the nascent design struggled to coalesce, beset by increasingly intractable problems. “After conducting his analysis, Jimmy was forced to leave his job as a result of the demands of his chemotherapy treatment.” This adversity became a significant catalyst in his relentless battle against cancer. “Our primary aim was to create a functional prototype, with the intention of manufacturing a limited batch of bicycles within the United States – essentially realizing the quintessential American Dream,” Michel explains.

So Jimmy and Michel fashioned the corporate ‘RD (Experience Totally different) Kustom & Design’ and hatched a plan to current the completed bike at a few of Europe’s most prestigious bike occasions. Initially, they faced the daunting task of bringing their innovative idea to life by designing a functioning motorcycle.

“We convened to conceptualize the design and arrived at an unembellished roadster characterized by a streamlined tube-like body, flanked by aluminum entrance and exit blocks that cradle a V-twin engine.”

With the most effective strategy determined, Jimmy initiated the project by creating a precise photogrammetric scan of the engine’s storage compartment using his mobile phone. Utilizing advanced computer-aided design (CAD) software, he modeled each component of the bicycle in Solidworks 3D, subsequently creating functional prototypes via 3D printing. As Jimmy carefully crafted his design, he meticulously considered each component’s role, often creating multifunctional elements to optimize performance.

Jimmy drew inspiration from Voxan Motors’ and Buell’s bike designs, crafting a pressure-member-type chassis for the body. The engineer created a innovative design featuring ultra-lightweight yet remarkably potent aircraft-grade aluminum, which formed a tubular double spine and incorporated distinct “blocks” at the entrance and rear, cleverly attaching to the Buell motor.

With Jimmy’s innovative designs in mind, Michel collaborated with a local CNC expert who possessed a cutting-edge 5-axis machine, offering a cost-effective solution to bring his concepts to life without relying on expensive casting techniques.

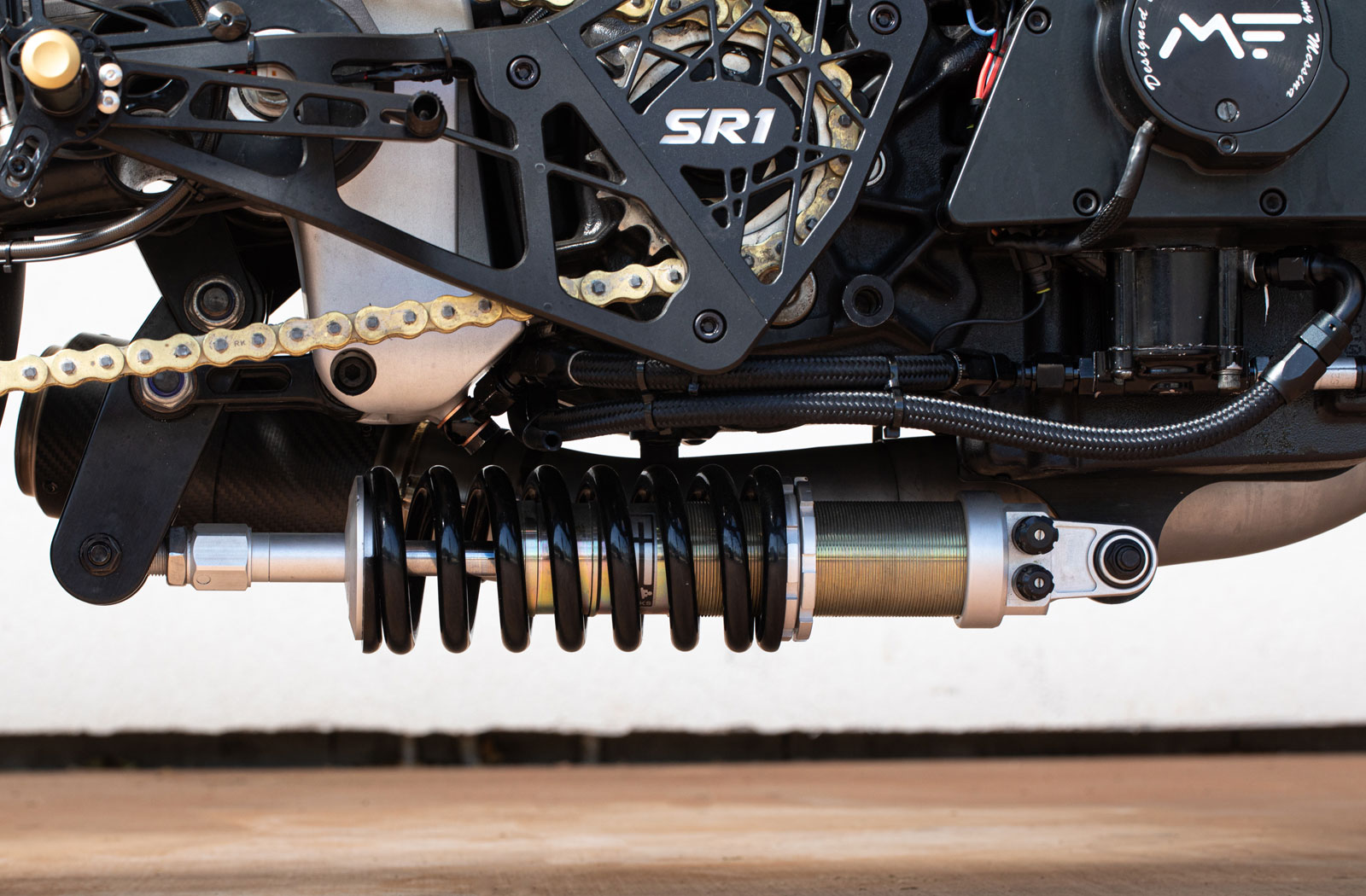

The aluminum “entrance block” securely fastens to the apex of the entrance cylinder’s v-twin configuration, forming the neck of the chassis. As the consumption increases, a secondary flow is created, which directs air upwards towards the airbox situated at the front end of the fuel tank. As for the rear block, this component plays a crucial role in supporting the back of the engine while also functioning as an oil tank, shock absorber mounting point, and swingarm pivot point.

The body’s spine is constructed from high-strength 7075 aluminum tubing, which precedes the welding of mounting plates at each end. The entrance finish is secured in position by a bespoke trio of CNC-machined bushes, while the single-sided swingarm and rear axle comprise custom-made, lightweight alloy components.

Michel explains that the body may indeed be quite rigid in its limitations. The bike seamlessly navigates curves, maintaining a precise trajectory. It’s very responsive!”

The front-end braking and suspension system of the motorcycle features components sourced from a Ducati 1198 donor bike, with Jimmy being the individual responsible for the procurement. The bike features a setup consisting of 1,198 forks, accompanied by a pair of Brembo brakes and a single 17-inch Marchesini wheel. The rear wheel, also a product of the renowned 1098 Marchesini lineage, was specifically designed to complement the bike’s single-sided swingarm setup. It features additional Brembo hardware for enhanced performance and braking capability.

With a setup akin to Buell’s innovative, reverse-mounted mono-shock, Jimmy designed a rear suspension system that mirrored the pioneering work of this renowned manufacturer. Collaborating with French suspension expert EMC, Jimmy’s team crafted a bespoke shock absorber featuring a unique linkage system conceived and designed by the rider himself.

As the use of aluminum persisted, further advancements were made in crafting an all-aluminum bodywork. Perched at the apex of the robust torso is a bespoke airbox-gasoline tank ensemble, meticulously crafted by Cedric from CRM in his own skilled hands. The wasp-like tail unit is another intricately crafted component, featuring winglet-style spoilers on both sides of the saddle. Here is the rewritten text:

Despite its compact size, Jimmy cleverly accommodated the bike’s battery and Motogadget M.Unit electronics controller within the tail unit and subframe, neatly integrating them along with the built-in rear-end lighting.

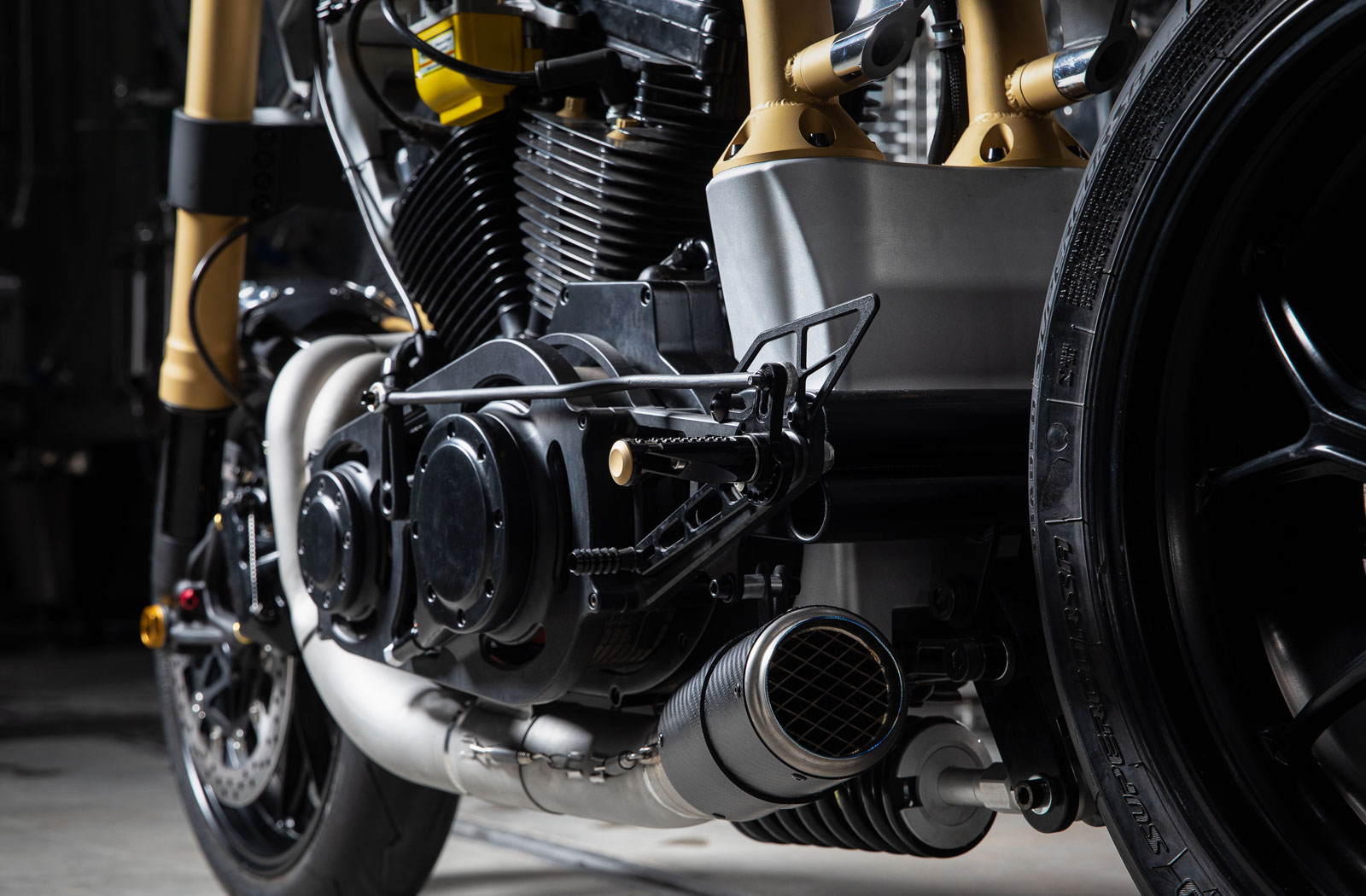

Handcrafted elements on the RD Kustoms SR1 elegantly complement the distinctive diamond-shaped headlight housing, where two LED lamps illuminate the surrounding area. The custom-designed foot controls and their unique mounting hardware are matched by the one-of-a-kind carbon fibre entrance fender, which is further enhanced by the specialized brackets that support its sleek design. In reality, as Jimmy noted, he designed and engineered nearly all aspects of the engine, excluding only a few minor components, a testament to his exceptional skillset that few could match.

The Buell S1 Lightning’s 1203cc V-twin engine delivered 101 horsepower and 90 Newton-meters of torque, but struggled to move the motorcycle, which tipped the scales at over 200 kilograms. Compared, the v-twin engine is discreetly situated within a lightweight, predominantly aluminum chassis, rendering its performance statistics all the more impressive. By limiting himself to minor adjustments in consumption and exhaust systems, Jimmy effectively constrained his engine upgrades.

The engine’s air supply is currently fueled by a duo of 39mm Keihin FCR carburetors, each equipped with high-flow filters and situated within a bespoke airbox designed specifically for this purpose. Jimmy chose a bespoke two-into-one header setup, which terminates in a sophisticated SC Venture muffler, its exhaust note a distinctive hallmark of his vehicle’s performance capabilities. To ensure a reliable spark, he installed an Accel Supercoil, while delegating the task of delivering power to the rear wheel to an Evolution Industries major belt drive.

The completed consequence here speaks for itself; nonetheless, to put the RD Kustoms SR1 to its ultimate test, Jimmy and Michel took the bike to one of the most esteemed international v-twin building competitions, the AMD European Bike Building Championships.

The new bike made its debut in Italy at the AMD European Championships’ final event, according to Michel. Jimmy’s bike emerged victorious, winning the prestigious ‘Best of Present’ award among a field of 70 entries from highly accomplished workshops. The victory also secured him a spot at the 2023 World Finals.

With this additional project underway, Jimmy had already commenced building an even more impressive RD Kustoms creation. This time, he intends to embark on an extraordinary project: constructing the engine of the bike from scratch, a truly impressive achievement. The sleek new bike is poised to make its world premiere at the Verona Motorbike Expo in January 2023, before traveling to the United States for a showcase appearance at Daytona Bike Week.

As he wraps up the discussion, Michel notes that this venture has enabled him to collaborate with his son on starting their business, RD Kustoms? Despite experiencing intense discomfort from his innovative treatment’s unforeseen consequences, he single-handedly conceived, fabricated, and assembled a remarkable 100% of this exceptional bicycle entirely by himself. In a surprising turn of events, the entire ordeal unfolded within the confines of a household storage space – a mere coincidence that echoed back to 1903 when the founders of Harley-Davidson first established their iconic brand? I sincerely hope that my son’s aspiration to become a renowned builder and engineer is fulfilled, and he receives the support he needs as he perseveres through his ongoing battle with cancer.

We sincerely hope so too.