During my most recent trip to China, I had the opportunity to explore various companies and manufacturing facilities within the rapidly evolving micromobility sector. While many well-known companies boasted impressive names and reputations, one unassuming firm caught my attention by quietly underpinning numerous top-tier e-bike manufacturers globally.

Meet Lishui, a corporation that has likely flown under the radar but has probably supplied products you’ve used without realizing it.

Contained in the controller maker’s nondescript buildings are a sequence of laboratories and manufacturing halls the place R&D and manufacturing happen. The company specialises in designing and manufacturing controllers, the central processing units of electric bicycles, as well as various other electronic components used in e-bikes and e-scooters.

Want a behind-the-scenes glimpse of how you can achieve your unique style? Follow along on my tour in the video below. Continuously work on mastering all relevant details.

As I delved into the facility, it was impossible to ignore the clusters of electric bicycles neatly aligned and spread throughout the labs. Several top-tier e-bike manufacturers from both North America and Europe have produced numerous innovative models.

The businesses you’re currently considering have had their bikes on site for a while. So have been the others. The gathering boasted a formidable assemblage of e-bike industry influencers. Despite Lishui’s lack of transparency regarding product usage, I am unable to identify title names. I’ve had to obscure every bike’s identity within the video and images, as many of them are novel, unlaunched designs that arrive in Lishui ahead of time for testing purposes, featuring cutting-edge controllers and drivetrain components from the company.

Despite their impressive statistics, the numbers tell a compelling story on their own: more than 1,900 customers worldwide have put their trust in Lishui, while its controllers have been sold to over 13 million users globally. In Europe, one-third of all e-bikes on the road rely on Lishui controllers to get moving.

The journey to success has been arduous and devoid of shortcuts. Since its founding in 1979, the corporation has been around, initially producing motor controllers for various industries. As the e-bike industry matured and came to fruition, Lishui shifted its focus solely to micromobility controllers by 1997.

Unlike numerous e-bike component manufacturers, Lishui sets itself apart by handling all its software development and hardware manufacturing internally. There’s no offshoring or outsourcing; instead, they have a dedicated team of nearly 60 in-house engineers working simultaneously on both hardware and software aspects.

Many of these engineers have spent over a decade with the corporation, allowing them to cultivate and retain the kind of specialized knowledge and skills that typically gravitate towards those at the top.

Lishui’s merchandise cater to three primary markets: low-power 250W controllers serving the European e-bike sector, higher-power 500W to 2,000W controllers targeting the North American market, and bespoke controllers featuring customized designs tailored to accommodate unique battery constraints and specific use cases. The company has fostered strong relationships with leading battery manufacturers over the past decade, enabling seamless integration of its controllers directly into their battery systems.

While some companies design standardised controllers, Lishui stands out by offering a custom-built IoT suite that enables seamless connectivity between devices, allowing businesses and end-users to remotely monitor and control their controllers via mobile phones, effortlessly adjust or modify settings as needed.

With the best approach in mind, Lishui has broadened its reach by developing and manufacturing innovative Bluetooth-equipped handlebars that capitalize on its precise control systems’ enhanced capabilities.

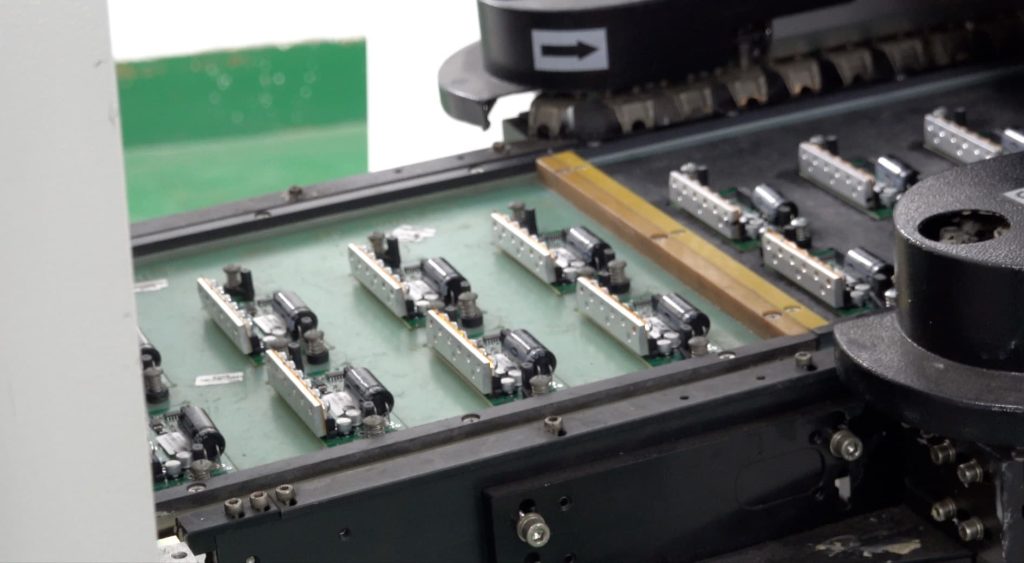

But crafting effective visual design elements is only the beginning of a successful endeavour. Lishui also manufactures high-tech components in-house, leveraging rigorous quality control measures and spot inspections to guarantee the precise production of each component.

Significant portions of our circuit board manufacturing take place on-site, with Lishui operating its own extensive fleet of industrial-scale soldering machines within our premises. Although a few hand-soldering tasks are performed on larger components, similar to those for thicker power cables.

Subsequently, the circuit boards progress through a series of mounting phases, where they are encased within an extruded aluminum enclosure and then filled with potting materials to protect the electronics from water ingress.

Once the controllers have completed the manufacturing process, they move on to the inspection stage, where they are connected to a sophisticated testing rig that subjects them to a rigorous series of 76 distinct tests. Each controller undergoes rigorous testing to ensure that every product exiting the manufacturing plant meets exacting standards for quality and performance.

Unexpectedly, I was given the opportunity to witness multiple features of the production facility that had not been on my radar. For example, the company’s founder, Mr., Xu, a self-proclaimed green thumb, has transformed every available inch of the factory complex’s floorspace into lush, sprawling gardens.

He has been gifted a personal greenhouse for his ornamental plants, in addition to larger facilities dedicated to growing food throughout the winter months. The property features lush vines and shrubs, with a sizable farm situated behind one of several warehouses, where meals are cultivated for the on-site cafeteria serving the factory’s employees.

In actual fact, Mr. As a symbol of humility and egalitarianism, Xu dines on the same cafeteria fare as his colleagues every day, an uncommon yet endearing trait. Across various manufacturing facilities, I’ve observed exclusive spaces designated for top-tier executives to dine; conversely, it’s heartening to witness a harmonious atmosphere where everyone from newly hired staff to the company’s visionary founder enjoys their lunch together without distinction.

The impact on controller standards is negligible, as manufacturers continually refine their products to meet evolving market demands. Possibly not. As one meanders through lush vegetation, a profound sense of well-being arises, complemented by the understanding that even executives are not isolated from reality, ultimately fostering a more harmonious work environment. Despite everything, perhaps that lingering concern for quality subtly shapes the final product.

During my visit to Lishui, I transformed from being largely unaware of this influential company’s capabilities as a controller producer to gaining profound insight into their ability to supply vast quantities of high-quality controllers to global e-bike giants.

It ultimately hinges on their profound understanding of the subject matter, unwavering commitment to self-improvement, and meticulous scrutiny for excellence.

As I gaze upon the sea of stealthy e-bikes lingering around the office corridors and clustered near the CEO’s monitoring station, it suddenly dawns on me that I’ve been holding onto a stash of Lishui controllers at home for far too long.