The world’s first 100-megawatt (MW) class heavy-duty truck supercharging station, the Sichuan Yuanqi Xingguang Heavy-Responsibility Truck Megawatt Supercharging Station, formally commenced operations yesterday in Beichuan Qiang Autonomous County, Mianyang Metropolis, Sichuan Province. This facility is constructed on Huawei‘s Megawatt Supercharging know-how.

The Sichuan Yuanqi Xingguang Heavy-Responsibility Truck Megawatt Supercharging Station serves as a megawatt-class supercharging demonstration web site for medium-to-short-distance bulk materials transport inside Beichuan’s sand and gravel mines. Developed by Sichuan Yuanqi Xingguang Digital Vitality Know-how Co., Ltd. with an funding of 150 million yuan (20.86 million USD), the station spans an space of 70 mu (roughly 11.5 acres).

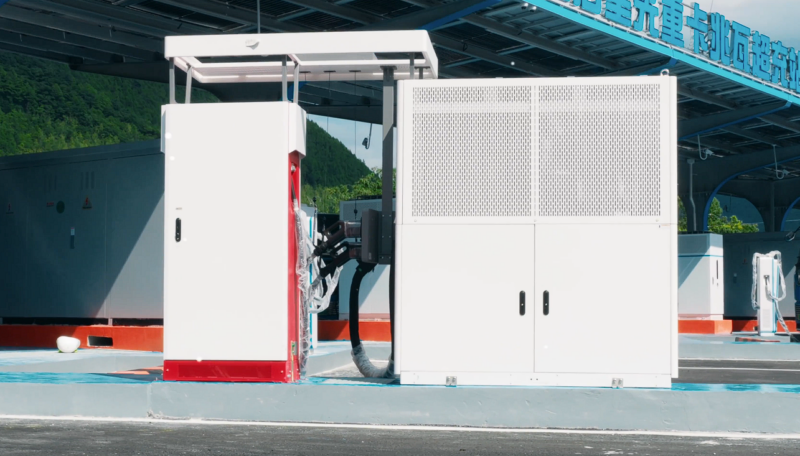

With a designed energy capability of 100MW, the station is provided with 18 x 1.44MW supercharging bays and 108 x 600kW liquid-cooled supercharging bays. It’s designed to serve as much as 700 electrical heavy-duty vans every day, with a projected every day charging quantity exceeding 300,000 kWh. The power additionally integrates a virtually 1MW photovoltaic carport and two 215kWh wind-liquid clever cooling power storage models.

Utilising Huawei Megawatt Supercharging tools, the station is appropriate with “3.5C” supercharging heavy-duty vans, enabling drivers to attain “cost for 5 minutes, drive for 100 km.” Truck homeowners are projected to avoid wasting 1.5 yuan (0.21 USD) per kilometre in power prices, amounting to 150,000 yuan (21,000 USD) yearly, successfully “saving the price of a truck in three years.” For station operators, the increase in charging effectivity is anticipated to enhance operational effectivity by over 15%.

A key innovation of the station is its enhanced grid friendliness. Huawei’s answer integrates good photovoltaics and grid-forming power storage to create a “source-grid-load-storage microgrid.” This microgrid can function each linked to and independently from the primary grid, successfully mitigating the affect of high-power charging on the grid and addressing stability issues. Moreover, the microgrid leverages VPP (Digital Energy Plant) know-how to work together with the grid, maximising the consumption of renewable power, decreasing prices via peak-valley arbitrage, and boosting income, thereby reaching “automobile, pile, and grid” synergy. The “PV-storage-charging” built-in answer deployed on the station generates roughly 5,000 kWh of inexperienced electrical energy every day. The electrification of industrial quality vans is projected to additional cut back carbon emissions by 45,000 tons yearly.