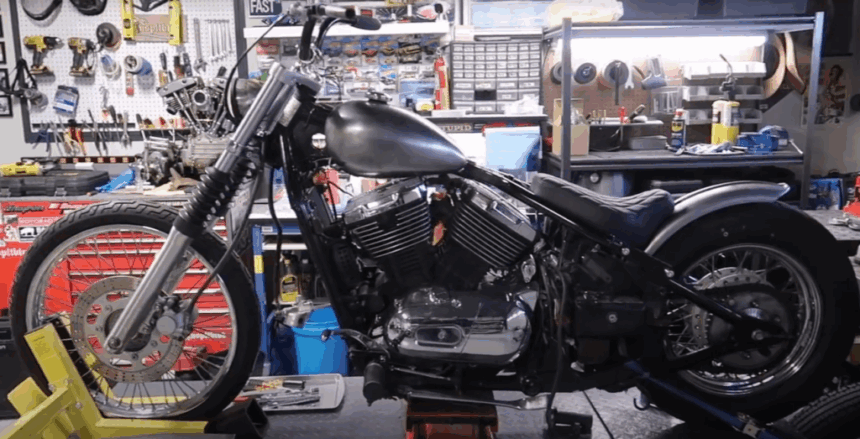

At present’s mission focuses on making essential adjustments to a Vulcan construct. Early within the course of, the workforce discovered a difficulty with the gasoline tank that didn’t permit for correct coolant line clearance. To repair this, they selected to make use of a completely different tank that can match higher and permit the strains to run easily.

After updating the tank plan, the workforce labored on mounting the seat and fender. They created sturdy brackets to ensure the seat and fender keep safe with out utilizing additional struts. The subsequent steps embody placing again the facet covers and planning the exhaust pipes round these elements.

Key Takeaways

- The present gasoline tank wanted to be switched resulting from clearance points.

- Seat and fender mounting options had been custom-made for stability and magnificence.

- Remaining steps will embody becoming facet covers and planning the exhaust.

Vulcan Gasoline Tank Mounting Problem

Evaluating Excessive Mount and Center Mount Types

There are two important kinds of tank mounts for the Vulcan: excessive mount and heart mount. The excessive mount has its mounting tab close to the highest of the tank, whereas the middle mount model locations the tab nearer to the center.

| Mount Sort | Tab Location | Impact on Set up |

|---|---|---|

| Excessive Mount | High | Can block coolant strains |

| Middle Mount | Center | Leaves area for strains |

The tank purchased for this mission was a excessive mount mannequin.

Points with Coolant Line Clearance

With the excessive mount tank, the mounting tab will get in the best way of the coolant strains working below the body. The clearance is just not sufficient, making it exhausting to route the strains with out awkward changes.

A attainable repair, like welding a bung, was thought of however didn’t look or match proper for this mission.

Steps for Changing the Gas Tank

As a substitute of forcing an answer, the present excessive mount tank might be saved for a unique construct. The plan is to purchase a heart mount tank in order that the coolant strains can correctly match beneath.

Subsequent Steps:

- Save excessive mount tank for later.

- Buy heart mount tank.

- Set up new tank, permitting area for coolant strains.

This strategy ought to preserve all the things neat and make future upkeep simpler.

Seat Mounting Options

Utilizing Pre-Drilled Holes for Seat Attachment

He began by utilizing an current gap within the body to safe the entrance bracket of the seat. This methodology helped anchor the seat without having to drill new holes. By making use of what was already there, he saved time and saved the mounting course of easy.

Including a Welded Cross Bar for Help

To carry the rider’s weight, a help bar was welded throughout the mounting factors. This bar gave the seat a stable base and stopped it from sagging or shifting. The additional power from the welded bar made the mount a lot sturdier.

Seat Help Overview:

| Technique | Objective |

|---|---|

| Pre-drilled gap | Entrance seat bracket mount |

| Welded cross bar | Weight help |

Additional Bracket to Forestall Seat Shifting

To cease the seat from transferring facet to facet, he made one other bracket. This bracket connects from a gap within the body to the welded cross bar. Drilling a gap and bolting this bracket in place locked the seat so it stayed put. As soon as welded, the seat didn’t shift or wobble.

Attaching and Securing the Fender

First Fender Attachment Spot

The rear fender began with one mounting spot, positioned to maintain issues as regular as attainable. There was no plan so as to add fender struts, so the look would keep clear and easy. So as to add extra safety, one other spot was chosen for a second attachment. This is able to be certain that the fender doesn’t shift or shake whereas using. Utilizing two factors helps preserve all the things agency.

A fast record of the steps for the preliminary mounting:

- Decide the primary spot for the fender.

- Bolt the fender down.

- Test for motion and stability.

Welding the Aspect Bung and Constructing the Second Bracket

For the second mounting level, a steel bung was welded onto the facet of the fender. This small steel piece allowed a bracket to be connected. The bracket, produced from scrap materials, wanted to be drilled for a bolt. After shaping and drilling, the bracket related the fender to the body. Utilizing these two spots gave the fender robust help with out additional struts.

Supplies Used

| Half | Objective |

|---|---|

| Weld-on bung | Additional mounting location |

| Metallic bracket | Connects fender and bike |

| Bolts | Secures bracket in place |

By taking these steps, the fender stayed agency and matched the easy look. No additional help rods had been wanted. All the pieces lined up and saved the fender from transferring round.

Aspect Covers and Pipe Adjustment

Placing the Aspect Panels Again On

The subsequent step is to reattach the facet panels earlier than engaged on the pipes. That is essential as a result of it helps verify if the pipes will stumble upon the covers later. The facet covers must be in place so you’ll be able to form and place the exhaust accurately.

Steps:

- Line up the facet covers with their mounts.

- Fasten them securely.

- Test that all the things sits flat and doesn’t transfer.

| Half | Motion |

|---|---|

| Aspect Cowl | Reinstall and safe |

| Mount Factors | Test alignment |

Deciding on the Rear Exhaust Path

Earlier than constructing the exhaust, planning the route is essential. For the rear pipe, the plan is to have it exit and run below the plastic on the again. The plastic piece in the best way will must be trimmed off. This offers sufficient room for the brand new pipe and avoids contact with the facet cowl.

Issues:

- The route should clear all different elements.

- The plastic blocking the pipe must be reduce.

- Double-check clearance from all panels.

Guidelines:

Subsequent Steps within the Construct

Tank Replace:

The present excessive tunnel tank can’t be used as a result of the mounting tab blocks the coolant strains. A brand new tank with a center mount might be ordered, so the coolant strains match beneath. The unique tank might be saved for an additional mission.

Seat Progress:

- The entrance bracket for the seat makes use of an current gap for mounting.

- A help bar was welded to carry the rider’s weight.

- There’s one mounting level now, with plans so as to add one other utilizing a bracket from a gap to the help bar, so the seat stays regular.

Rear Fender Work:

- The fender has one mounting level and wishes one other for additional stability.

- To keep away from utilizing fender struts, a bung might be welded to the fender’s facet.

- A bracket might be made to bolt the fender down at a second level.

| Half | Step Accomplished | Subsequent Step |

|---|---|---|

| Gasoline Tank | Ordered new right tank | Set up when it arrives |

| Seat | Mounted, wants help | Weld second bracket |

| Rear Fender | One mount in place | Add second mount, weld |

Aspect Covers and Pipes:

- Aspect covers might be reinstalled to verify pipe clearance.

- The rear pipe might be rerouted below the plastic, which must be eliminated to create space.

- Work on the exhaust pipes will proceed within the subsequent stage, ready for the brand new tank to reach.