Over the past 11 years, Portland has been proud to serve as a hub for some of the country’s most exceptional custom builders. Conceived by See See Bikes founder Thor Drake, the ‘One Bike Present’ is a unique amalgamation of various custom motorcycle styles. Among the numerous modified bikes showcased last year, one particular model stood out from the rest. At the event, San Francisco-based Hugo Eccles of Untitled Bikes made an appearance alongside his custom-built, zero-emission electric motorcycle, the Zero XP. By the time the weekend arrived, one of the most thoroughly photographed and discussed machines in recent history had taken center stage. Following the settling of the mud, we seized the opportunity to discuss with Hugo the significance of this remarkable venture for a brief few minutes.

Our partnership with Zero Bikes was born from a shared passion for innovation and sustainability.

The northern region of California has emerged as the hub of the electric vehicle (EV) industry in the United States. As soon as I relocated to San Francisco in 2014, I rapidly initiated outreach to several electric motorcycle companies, requesting test ride opportunities. I had the privilege of piloting the Mission R, Alta Redshift, Energica Ego, and Zero SR, which propelled me into a realm where designing a custom electrical motorbike became an urgent imperative.

The Zero Motorcycles community has been abuzz with enthusiasm for my custom Ducati Hyper Scrambler, which recently gained exposure on Jay Leno’s Garage. We collaborated effectively for approximately two years, poised to tackle a project that aligned with our joint aspirations. Since its inception in 2008, Zero Motorcycles has proudly operated within the industry for a remarkable 14 years – an impressive tenure rivaled only by one other electric motorcycle manufacturer. Notably, this milestone marks the first-ever factory-authorized custom SR/F model globally. I’m humbled by their faith in me, and I strive to have lived up to the moment’s significance.

Were there any reservations or concerns when taking on the project to develop an electric motorcycle?

I had no qualms about embarking on the venture, but I knew I needed to approach it with careful consideration. For a seasoned producer poised to capitalize on the burgeoning demand for electric motorcycles, the opportunity to design on a new platform was a rare and coveted chance. This offered a chance to thoughtfully explore and potentially shape the emergence of a new industry’s foundation. Ought to electrical mimic gasoline? Should a document have its own personal identity verification? What likelihood exists to initiate a discussion on the design principles underlying electrical systems? The zero XP initiative is intended to spark a discussion and drive innovation in the field.

The endeavour received a substantial contribution from the Smith Foundation, a philanthropic organisation dedicated to supporting innovative projects. The project’s timeline spanned two years, with a meticulous planning phase of six months preceding the actual construction period.

The base model mannequin for the Zero XP is a 2020 Zero Motorcycles SR/F. When we started collaborating with Zero in mid-2018, the SR/F was still roughly 10 months off from production. Given the highly sensitive and proprietary nature of the project, I deemed it essential to place the Untitled Bikes San Francisco workshop under a strict lockout to ensure the confidentiality and security of our intellectual property.

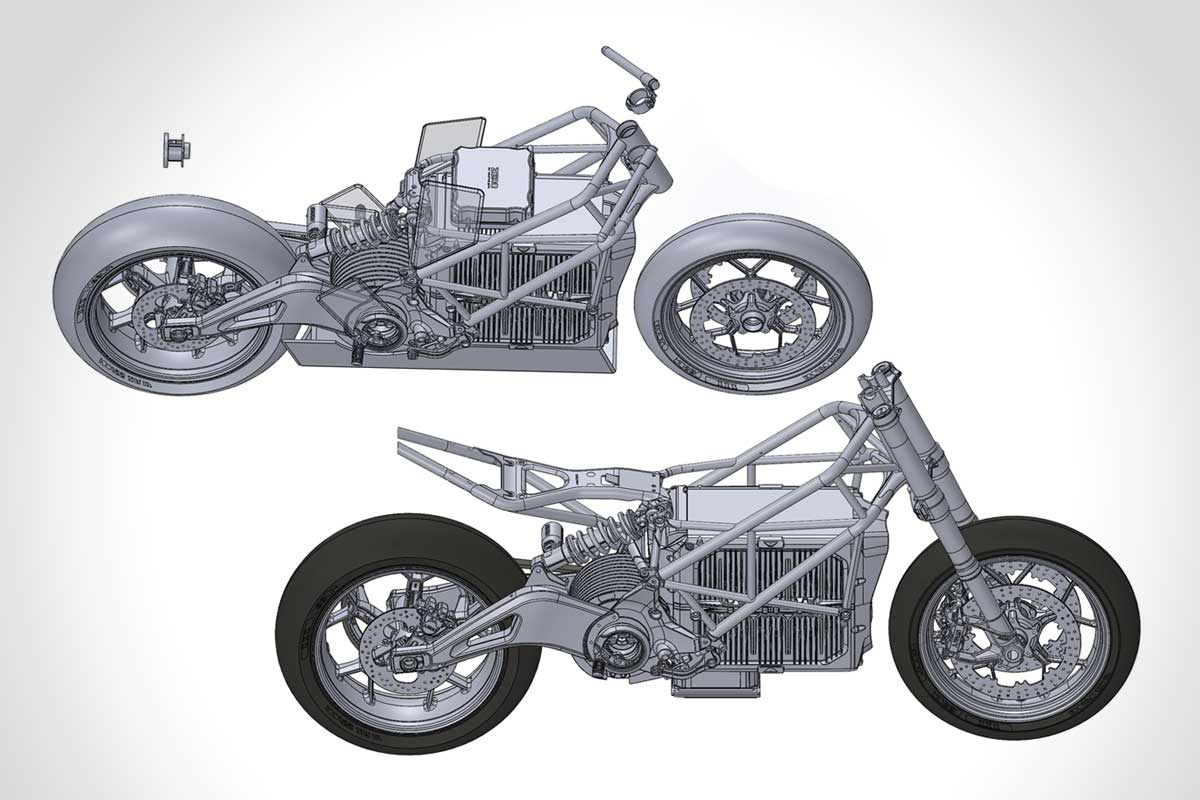

After a 14-week design phase, I created approximately 500 pages of sketches, experimenting with diverse layouts before settling on a concept featuring a central electrical core anchored by an analog framework. By December 2018, I possessed a pre-production Zero chassis, motor, and battery, enabling me to verify design assumptions and initiate detailed 3D computer-aided design (CAD) modeling with confidence. With Zero’s provision of CAD data for the SR/F, I spent the subsequent 10 weeks immersed in a meticulous endeavour, dedicating over 1,500 hours to refining my skills in 3D-CAD modeling.

Despite its public launch in March 2019, I didn’t manage to get my hands on a production Zero SR/F until mid-April 2019, likely due to the unprecedented demand for this brand-new model. Within a brief span of weeks, I had the opportunity to familiarize myself with the bike before embarking on the dismantling process. Despite the setbacks, I aimed to complete the 3D-CAD design, procure the necessary CNC parts, and finally assemble my Zero XP.

Built just five weeks prior to its international debut at the Goodwood Festival of Speed in the UK, the motorbike had been assembled with precision and care. Unencumbered by terrestrial duplicates, Goodwood’s singular allure drew 200,000 visitors, broadcasting its magic across 21 nations, and generating a staggering social media footprint of 1.3 billion – leaving me with little hope of passing up the opportunity.

Had unexpected challenges arisen while building a bespoke electric motorcycle, forcing an unconventional approach to overcome them?

My preferred workflow strategy is rooted in the iconic philosophy of Lotus Cars’ founder Colin Chapman, who advocated for “simplifying and adding lightness” to optimize performance. However, this approach presented a unique challenge during the Zero XP project. With a gasoline-powered vehicle, I typically start by disassembling the engine to its bare essentials – the rolling chassis – before meticulously reassembling it with all necessary components in their proper places. Naturally, certain components require replacement over time – namely, the fuel tank, carburetors, and exhaust systems – which presents opportunities for innovation and cost reduction. It became starkly apparent that every single one of the SR/F’s plastic parts was entirely unnecessary for the motorcycle’s electric motor to function properly. What would a bike for personal transportation look like if we were designing from scratch, without any preconceptions or influences from existing motorcycles? After conducting research on stripping down a motorcycle to its bare essentials, I realized that while you wouldn’t typically install a traditional tank on an electric motorbike, it is crucial to have knee panels to control the vehicle effectively. The initial framework for the Zero XP’s design was established, ultimately yielding a comprehensive outline of interfaces for both machine and human management.

What sparked your curiosity about the bicycle’s design is its unconventional fusion of vintage and modern elements. The frame’s distressed finish, reminiscent of a well-loved classic, sits in contrast with sleek, high-tech components like disc brakes and carbon fiber wheels. This juxtaposition may be attributed to the designer’s desire to blend nostalgia for the early days of cycling with their passion for innovation.

Most designers, when faced with an electric motorbike, tend to focus on the future. But I opted instead to gaze into the past. In the midst of the 1980s, a revolutionary surge in bicycle design and diversity transformed the landscape. Sturdy parallels seem to exist between the evolution of gas-powered motorcycles and the present landscape surrounding electric vehicles. Traditionally, we’ve been on the cusp of embracing an era where electricity has become the norm. As I pondered on what a modern electric motorcycle would look like with the advantage of 135 years of technological progress, In the alternate reality, the Zero XP is not intended to serve as a futuristic motorcycle, but rather as a contemporary motorbike from that parallel universe.

What custom modifications did we implement on the Zero SR/F motorcycle to enhance its performance and aesthetics?

Beneath the surface, the Zero XP retains its underlying similarity to a standard SR/F, with the exception of relocated components and added custom electronics, as the braking, traction, and stability systems remain unchanged. While maintaining the distinctive swingarm, I retained its corresponding suspension, wheels, and braking system for seamless integration and functional simplicity. The entire original equipment manufacturer (OEM) bodywork has been replaced with bespoke custom panels, crafted using advanced computer-aided design (3D-CAD) software and precision-fabricated from a combination of lightweight materials, including aluminum, glass-reinforced plastic (ABS), and polycarbonate. With the absence of Zero XP in 3D-CAD, designers can effortlessly reorder newly added components and panels with a mere click of a button.

Were there any particularly challenging aspects to designing and building a bespoke electric motorcycle from scratch?

Learning about this innovative technology presented a significant learning curve for me. To quickly refresh my familiarity with the Zero SR/F and its features, allowing me to discern what was essential and what could be omitted. Knowing I could readily tap into Zero’s impressive technological expertise throughout the project. In my previous role, I had the opportunity to verify with the team whether the idea I proposed was feasible.

Another issue was abandoning the fundamental principles and preconceptions about what a motorcycle should look like? It’s challenging to motivate oneself to challenge the status quo when there are so many assumptions rooted in conventional wisdom about fuel.

Compared to its standard counterpart, the Zero SR/F, the Zero XP (Experimental Package) excels in several key areas. For instance, it features improved aerodynamics, courtesy of its sleek fairings and wind deflectors, which enhance both stability at high speeds and rider comfort during long hauls. Additionally, the XP’s re-tuned suspension setup prioritizes a more composed ride over aggressive handling, providing an unmatched level of refinement on various road surfaces. Meanwhile, its unique seat design fosters greater rider mobility by allowing for easier shifting between sitting and standing positions.

Mechanically, the Zero XP’s performance profile is remarkably similar to that of a high-performance sportbike inventory SR/F, boasting identical features such as advanced braking systems, traction management, stability control, and others. Its efficiency is equally impressive: delivering an astonishing 140 ft-lbs of torque and accelerating from 0-124 mph in just 7 seconds.

What’s been the origin story behind your Zero XP so far?

The response has been wonderful. Jalopnik’s nomination of it as “the best bike on the One Moto Present” was an immense honour. Indian Bike’s Director of Product Design, Ola Stenegärd, formerly Head of Automobile Design at BMW Motorrad, where he was responsible for the highly acclaimed R nineT, called it a “gamechanger” – an accolade that doesn’t come much higher.

Are you on the lookout for innovative electric motorcycle projects or a step back towards fossil-fuelled vehicles?

Fully! We have a range of initiatives, both electrically and gas-powered, in development. What innovative endeavor! The project is developing an electric motorcycle designed for individual use in New York. A cutting-edge fusion of 1980s-style endurance racing and advanced electric powertrain technology awaits. Here is the rewritten text in a different style:

Our aim is to merge cutting-edge technology seamlessly with traditional analog elements, combining the best of both worlds in a modern superbike that embodies innovation and sophistication.

I am working on a project for a customer who has lost his lower legs and forearm. The project utilises the Aprilia Mana 850 as its foundation. From an ergonomic and value-based perspective, this undertaking presents a compelling opportunity. I’m also fulfilling a few orders for the Hyper Scrambler 2, a distinctive model featuring enhanced specifications, to customers in both Belgium and California.

While Hugo Eccles’ custom electrical motorbike undoubtedly sparks amazement, its true uniqueness lies in the overwhelmingly positive public reaction it elicits. While electrical bikes may face criticism from within the cycling community. With zero experience points, opinions appear to converge on a uniformly positive note. But surprisingly ordinary nonetheless. Here’s an improved version: Hugo’s innovative design offers a remarkably vivid and captivating vision of what the future of two-wheeled travel may hold.

As more nations transition away from fossil fuels and towards electric-powered transportation, the ascendancy of e-bikes appears increasingly inexorable. As technology advances, we may well grow accustomed to embracing innovative machinery like the Untitled Bikes Zero XP, readily accepting its integration into our daily lives.

UNTITLED MOTORCYCLES

Pictures by Ludovic Robert

ZERO SR/F XP SPECIFICATIONS

- Streamlined CNC-fabricated polymer panels featuring precision-crafted frosted polycarbonate trim.

- Customized seats, reupholstered in premium ultrasuede, bearing a discreet UMC logo?

- Precision-machined from high-strength, lightweight 6061-T6 aerospace-grade aluminum, the customized seat shell, nostrils, and bellypan deliver unparalleled performance and durability.

- CNC-machined fork brackets crafted from high-strength 6061 aerospace-grade aluminum, precision-engineered for unparalleled performance.

- The Aerospace Materials Specification ‘Ghost Gray’ experimental plane paint is a cutting-edge, high-performance coating designed specifically for the demands of aviation. With its unique blend of pigments and resins, this paint offers superior durability, UV resistance, and color retention, making it an ideal choice for enthusiasts and professionals alike.

- Zero SR/F body, modified

- What are the key features of Showa’s SFF-BP suspension forks?

43mm diameter tubes provide increased stiffness and reduced weight

Adjustable preload, compression, and rebound damping allow riders to tailor the fork’s feel to suit their riding style

Modified design ensures optimal performance in various conditions - Twin 320mm N-Gap floating entrance discs pair perfectly with twin J. Juan 4-pot calipers.

- Forged 3.5-inch x 17” SR/F alloy wheels offer a sleek and rugged entrance to your motorcycle’s design.

- The iconic Showa fork has been rebalanced to provide a silky-smooth ride and unparalleled handling capabilities.

- A high-performance braking system featuring a 240mm rear disc and J.Juan’s advanced single-pot floating caliper design.

- The Zero SR/F’s 5.50 x 17” forged aluminum rear wheel, coupled with a Gates Carbon Drive belt, effectively optimizes the motorcycle’s performance, providing a seamless ride and increased durability.

- Pirelli Diablo Superbike race tires – 180/60R-17 rear, 120/70R-17 front.

- Enhanced precision-milled CNC housing featuring integrated speed indicator and vibrant LED display.

- What motorbike enthusiasts crave most is a tailored riding experience, which is exactly what our customized clip-on bars provide. By incorporating an intuitive digital throttle within the design, riders can now seamlessly adjust their speed and control while navigating through twisty roads or cruising down highways. With this innovative feature, the thrill of the ride is elevated to new heights.

- Motorsport-inspired Mini LED display, seamlessly integrated within a sleek and sturdy custom high-Bracket.

- Customized-molded grips

- Ruffy’s 5-way thumb joystick features a custom-molded rubber cowl for enhanced grip and control.

- ISR brake grip with integrated switches, internally connected.

- Goodridge Sniper 2 Braided Chrome Steel Brake Lines?

- Precision-engineered CNC-machined 6061 aluminum footrest brackets feature integrated ABS heel guards for enhanced safety and durability.

- The Zero Cypher III display, seamlessly integrated into ‘tank’ design.

- Customised Zero firmware

- Customised and relocated battery charger

- Tank-mounted keyless M-Lock RFID ignition system

- What sleek modern design combines practicality with style? A customized anodized aluminum RFID key fob, of course!

- Motobox introduces a premium custom LED tail light array featuring integrated flip indicators for enhanced safety and style.

- Motobox {custom} LED panel edges

- 4XLED twin headlights

481lbs / 218kg

80-160mi / 130-260km

124mph / 200kmh