Toyota’s slow pace in the electric vehicle (EV) market has left many questioning its commitment to electrification. While acknowledging that Toyota lags behind Tesla in the electric vehicle (EV) market, Ted Ogawa, the Japanese automaker’s US chief, remains optimistic about the company’s prospects, insisting that it’s “closing the gap” in terms of EVs and innovative technology.

Toyota has lagged behind in transitioning to fully electric vehicles. Following a tumultuous debut, marked by a product recall, Toyota’s initial foray into the US electric vehicle market with the bZ4X has thus far struggled to gain significant momentum.

Among the more than 2.2 million Toyota vehicles sold in the US last year, a mere 9,329 were all-electric, a paltry 0.45% of the total.

The Toyota bZ4X’s sales trend has persisted over the past year, with a modest 1,897 units sold in March marking the exception rather than the rule. A mere 0.004 percent of the more than 486,000 Toyota vehicles sold during the first quarter.

Toyota is monitoring electric vehicle (EV) demand from buyers rather than waiting for government regulations to drive the shift. “Despite being absent from our lineup two years ago, the BEV was a much-needed addition, which is why we faced significant criticism.”

Following a period of internal development spanning nearly three years, Akio Toyoda, CEO of Toyota’s North American operations, asserts that the company has made significant strides in electric vehicles and innovative technology, finally “catching up” with industry leaders.

Toyota’s electric vehicle (EV) strategy has been criticized for being slow to adapt, but recent developments suggest the company is finally gaining momentum.

According to Ogawa, Toyota’s headquarters is building a singularly innovative production facility dedicated specifically to the manufacture of electric vehicles.

The cutting-edge “BEV Manufacturing facility” will boast several innovative technologies novel to Toyota. The company has officially unveiled its next-generation electric vehicle (EV) manufacturing line, a process modeled after the successful Giga casting approach pioneered by Tesla.

Toyota claims its vast repository of mold data will facilitate accelerated production. The corporation aims to significantly reduce the lead time for mold modifications to approximately 20 minutes, a significant decrease from the current 24-hour timeframe.

Various innovative technologies, such as self-propelled production lines and robots, are poised to enhance efficiency while reducing defects.

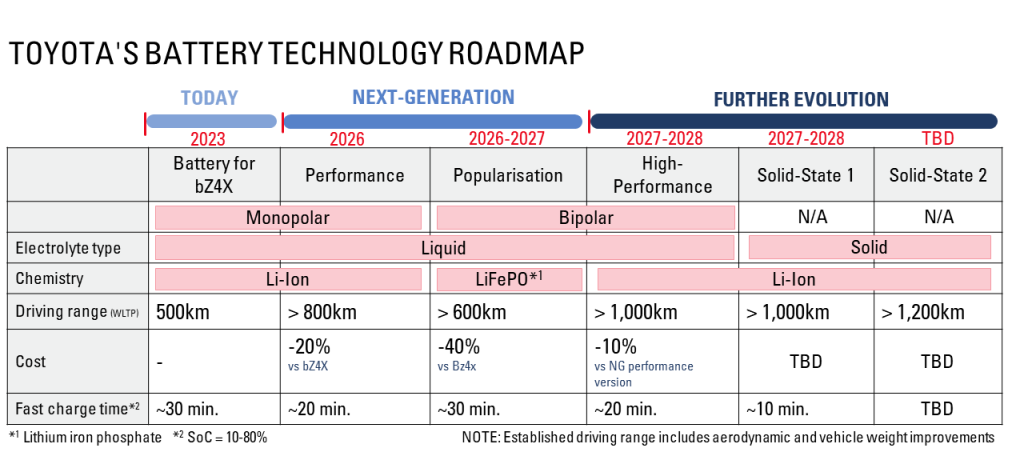

Toyota unveiled its new electric vehicle (EV) battery plans last summer, including the introduction of two advanced battery variants scheduled for release by 2027. Here’s an improved version:

The flagship ‘Efficiency’ battery boasts a remarkable range exceeding 800 kilometres, or approximately 497 miles, while offering a 20% price reduction compared to the bZ4X.

By 2026-2027, the “Popularisation” model is expected to debut with a significant feature – a staggering 600-kilometer range – a whopping 40% reduction in price.

By 2027-2030, Toyota intends to introduce a series of “additional evolution” batteries, accompanied by the rollout of solid-state batteries boasting an impressive range of over 621 miles on a single charge, with rapid recharge capabilities taking mere minutes, clocking in at 10 minutes precisely.

Ogawa suggests that the current transition period is akin to the initial 12 months of a multipath approach, mirroring the hybrid model we’ve already implemented. This will be followed by a plug-in hybrid, then a battery-electric vehicle (BEV), paving the way for its market introduction.

Although Toyota trails behind Tesla’s battery technology, as noted by Ogawa, it is actively closing the gap. According to Ogawa, Toyota is not only playing catch-up in electric vehicles (EVs) but also the broader ecosystem surrounding the BEV space, including home charging and power management.

Electrek’s Take

Toyota’s momentum is finally gaining traction. After a few years of lagging behind its rivals, the Japanese automaker has been investing heavily in electric vehicles and autonomous driving technology, and it shows. With the success of models like the RAV4 Hybrid and Mirai fuel cell car, Toyota is poised to make a strong comeback in the global market. Executives have repeatedly shared these insights with us thus far.

Despite electric vehicles (EVs) making up less than 0.4% of total US auto sales, Toyota may need to take additional steps to demonstrate its commitment to this growing market segment. Toyota plans to introduce solid-state EV batteries in 2021 and 2022, but it’s now expected that they won’t reach the market until at least 2028.

The integration of advanced technologies, such as gigacasting and automated manufacturing, is expected to boost efficiency; nonetheless, the release of novel electric vehicles is not forecasted until 2026.

Toyota recently invested heavily in US manufacturing, including a $1.4 billion commitment to build a new electric SUV in Indiana, distinct from its previously announced three-row EV model.

Can innovative fashion trends and cutting-edge technology help Toyota regain momentum in the rapidly evolving electric vehicle market this time around? What a unique goal! Here’s the rewritten text in a different style:

Please provide the original text so I can work my editing magic and deliver the revised version to you.