Growing up alongside his father’s unwavering passion for motorcycling, Vytautas caught the motorcycle fever from a young age. Despite this, he would eventually stumble upon the realm of customization.

After establishing a close friendship with bike engineer Mindaugas Silgalis, Vytautas often found himself joining him at his workshop in the evenings, where they would collaborate on various projects and tasks related to Mindaugas’ prized Harley-Davidson motorcycles. During late-night brainstorming sessions, the duo conceived the idea to create the distinctive K1100LT.

As Vytautas reminisces, his father surprised him with a thoughtful gift on his birthday in 2020 – a 1993 BMW K1100LT. I was thrilled at the prospect of tackling an initial, straightforward challenge and my father encouraged me to stay genuine, so that we could adventure together. I wanted to clarify with him what would be completed through some engineering.

Before the lengthy process of disassembling the K1100LT began, Vytautas’s inaugural custom project was already in full swing. For the next three years, he steadily worked on the construction project. While Mindaugas primarily handled the fabrication tasks, Vytautas and his father collaborated to oversee the construction process. Despite its unconventional appearance, performance was a priority, and Vytautas’s father’s engineering expertise proved invaluable in that regard.

Throughout the restoration process, Vytautas focused on improving the efficiency of his 30-year-old BMW by incorporating modern upgrades. Whenever possible, he utilized genuine BMW parts retrofitted from newer models. Starting with the distinctive spoked wheels, he combined elements from R18 and R1200C rims and hubs to effectively utilize the one-of-a-kind drive switch, incorporating its innovative features into his custom build. The brakes utilize all Brembo components, sourced directly from BMW donations. The bike in question did not feature a K1100LT hydraulic clutch, a high-efficiency component typically found on later models. Vytautas further enhanced the clutch upgrades by comprehensively rebuilding the gearbox in tandem with the engine and driveshaft, incorporating fresh gaskets, seals, and bearings to ensure a seamless integration.

The checklist for custom-made parts is, as expected, comprehensive; nonetheless, a few items require further elucidation. While the humble gas tank may seem unremarkable at first glance, its significance cannot be overstated. The initial tessellation design was prototyped using cardboard, after which Vytautas devoted a month to refining the components with a jig fabricated from 2mm aluminum plate. Mindaugas meticulously assembled the entire collection by carefully welding each piece together. An identical strategy was used to construct the tentacle-like 4-into-1 exhaust which has been paired with a bigger consumption and free-flowing Ok&N filter.

The custom-made aluminum fenders, along with the alloy triple clamp and numerous brackets, have been meticulously crafted to seamlessly integrate the newly installed components. A newly reworked rear suspension system, specifically crafted headlights, and a reborn subframe have been meticulously engineered and handcrafted from the ground up.

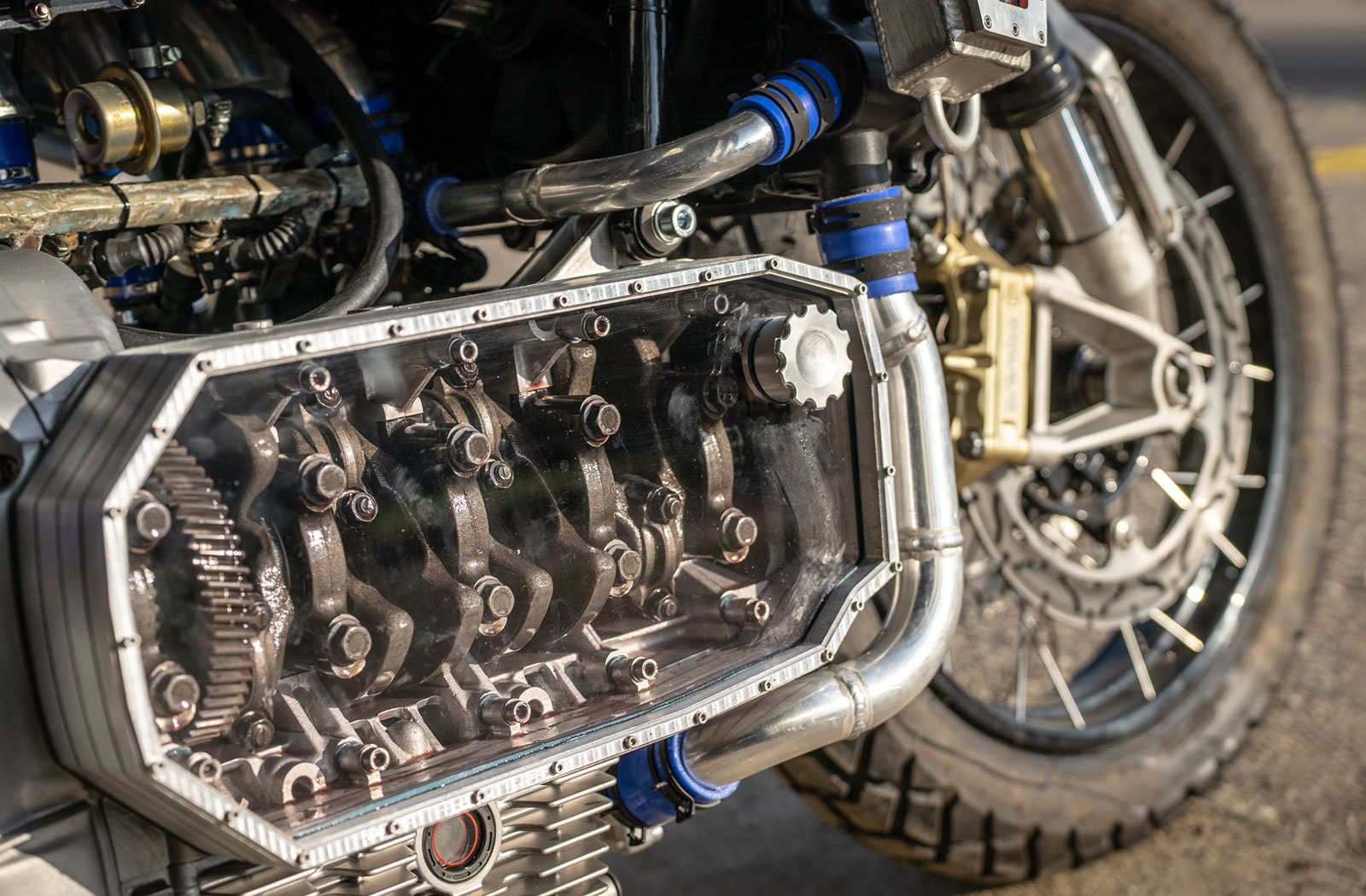

While the entire motorcycle undoubtedly demands attention, the real showstoppers are the engine covers, which prompt repeated glances. “The casing between the gearbox and the engine has been minimised to accommodate the starter and alternator, making it even more exposed,” Vytautas points out. The newly designed covers were engineered to provide an unobstructed vista into the inner workings. You don’t often get to witness a crankshaft and valves in action!

With the latest technological advancements, this K1100LT boasts a comprehensive overhaul of its electrical systems. Tapping into Motogadget’s extensive product range, Vytautas successfully completed the task. The Motogadget suite of upgrades features an intuitive m.unit controller, Wi-Fi enabled ignition, precision-crafted switches, a comprehensive wiring harness, and innovative bar-end flip alerts, among other enhancements.

The comprehensive custom overhaul also featured a bike equipped with numerous aftermarket components, including rear-set footpegs, smooth-operating hydraulic lines, and newly installed mirrors and handlebars.

Despite its unusual appearance, Vytautas finds that the bike performs exceptionally well. Compared to its previous form, the device is remarkably compact and lightweight. Was I unable to place it on the central support before? ”

Tragically, Vytautas’ father passed away before the project’s completion, but he is heartened that it can serve as a testament to others that even the most ambitious ideas can become reality with a modicum of ingenuity and perseverance. “When I first started dreaming of building a café racer, I thought I’d simply replicate something I found online,” he reveals, “but thanks to Mindaugas’ encouragement, I was inspired to take a completely new approach.” “I’ve never witnessed a motorcycle where the crankshaft is visible, let alone with the timing cover open.”