Nissan is gearing up for production of its highly anticipated next-generation LEAF, potentially launching as early as March of next year. As Nissan’s Sunderland plant presses forward with preparations for its brand-new electric vehicle, a pressing issue looms on the horizon.

Following the discontinuation of the iconic LEAF model earlier this year, Nissan is gearing up its Sunderland facility for a fresh start in the electric vehicle era.

Despite selling over 650,000 LEAF models worldwide, the introduction of new competitors has significantly impeded global sales. Since 2013, Nissan has been manufacturing the LEAF at its Sunderland, UK plant, having produced more than 280,000 units to date.

Nissan announced an investment of approximately £3 billion (or $4.2 billion) in November to enhance its capabilities in manufacturing electric vehicles, with plans to produce three new models.

Nissan is set to roll out electric variants of several of its most popular models, including the iconic LEAF, Qashqai, and Juke. The all-new LEAF is poised to begin production testing in August, marking a significant milestone in its development.

Nissan is poised to begin production of its next-generation LEAF electric vehicle as soon as March 2025, with initial trial runs expected to last approximately six months. Nissan’s electric vehicle debut may arrive sooner than year-end. However, this is contingent upon a seamless process unfolding.

Following significant investments, Nissan remains committed to manufacturing electric vehicles in the UK. Notwithstanding, it’s “not without its drawbacks,” consistent with Alan Johnson, VP of the company’s regional manufacturing division.

“It’s a real issue,” Johnson recently emphasized, adding that it’s a genuine concern. Constructing electric vehicles (EVs) within the UK can be viable, he noted, but only if all stakeholders align.

While countries compete in various areas, the UK faces diverse challenges among its own regions.

Johnson cited concerns over the scarcity of “robust insurance policies” and challenges in establishing a reliable regional supply chain. According to Johnson, a significant hurdle lies in the cost of power, namely the price. “The UK’s higher prices may result in a drastic reduction of earnings for consumers, with prices typically doubling those found in mainland Europe.”

Nissan readies itself for production of its next-generation LEAF.

To combat rising electricity costs, Nissan is significantly increasing its reliance on renewable energy at its manufacturing facility. Approximately one-fifth of the manufacturing facility’s overall energy consumption – approximately 250 megawatts per week – is sustainably sourced through on-site wind and photovoltaic installations.

Nissan aims to transition entirely to renewable energy, with no specified deadline. The company’s innovative features include the establishment of a state-of-the-art battery manufacturing facility to support production of its next-generation LEAF model, as well as another gigafactory located nearby.

Engineering Supervisor Man Reid announced the start of a fresh era at the plant. Notwithstanding, Reid emphasized that crucial modifications were necessary to unlock a production line that had been manufacturing ICE vehicles for over three decades.

As various automotive manufacturers have learned, the challenge of efficiently handling the considerable weight of electric vehicle (EV) batteries has driven demand for innovative technologies and equipment. Additionally, the company is investing in upskilling its workforce to support the production of electric vehicles.

According to Adam Pennick, plant boss, this situation brings forth unique hurdles of its own. Nissan intends to significantly expand its staffing levels at the manufacturing facility as production is poised for a substantial increase.

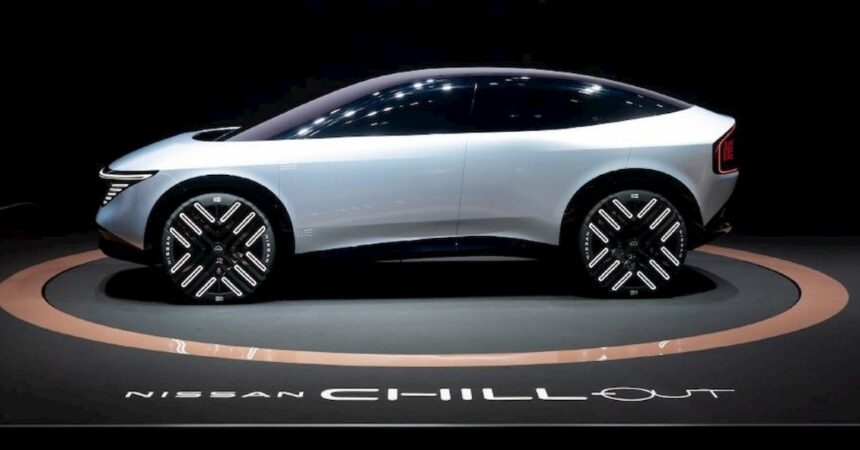

Nissan has unveiled a sneak peek at the next-generation LEAF with its Chill-Out concept. According to credible sources, the upcoming model is poised to undergo a comprehensive overhaul, transforming into a stylish crossover coupe with a reimagined design. While maintaining a compact size, the new model is poised to outdo its predecessors in terms of performance and design flair, ensuring it stays sporty and agile.

One supplier claimed their design resembled that of the Ariya, Nissan’s all-electric SUV. The company touted it as a “mini Ariya,” while another supplier made similar claims. Meanwhile, Nissan directed retailers that the revamped model would boast a groundbreaking design overhaul and a 25% boost in range to enhance its competitiveness.

Electrek’s Take

As the current LEAF model’s sales momentum wanes, a refresh is overdue. Despite a surge in electric vehicle (EV) releases, LEAF’s gross sales have plummeted across all major markets compared to the preceding year.

Meanwhile, Nissan’s Ariya is stepping up to fill the void. As of March, Nissan’s Ariya electric vehicle had achieved significant sales milestones: 4,142 units sold in the US and 4,050 units in Europe. As the next-generation LEAF prepares for its debut and Nissan readies itself to launch two electric SUVs, the automaker anticipates a surge in momentum.

What do you guys assume? Will Nissan’s revamped Leaf electric vehicle finally spark a resurgence in its flagging sales? Tell us your ideas within the feedback.