“As the urge to build another bike for himself grew insistent, Jeremy had been struggling to fit it into his busy schedule. But once he finally committed to the project, he devoted late nights and weekends to bringing his vision to life.” The biggest hurdle in tackling this bike project was actually starting it – developing a clear vision and locking down a solid plan proved to be the most challenging aspect for me. As the starting point for any endeavor, this challenge began with a formidable foundation. I dispatched the sketch to my acquaintance Daniel Maffett, who kindly produced a rendering on my behalf.

With his heart firmly set on using a Honda CB750 as the donor bike, Jeremy was fortunate that he didn’t have to go far to find one.

“Next to my store is a Honda dealership specializing in vintage CB models.” I revealed my proposal to the property owner directly. As we stepped into his storage facility, I was struck by the sheer number of makeshift shelters, or CBs, where individuals had sought refuge. He instructed me to select one. For reasons unknown, this product caught my attention, and I decided to bring it back to my store.

With a nod to vintage inspiration, Jeremy kickstarted his project by crafting a bespoke metal gasoline tank modeled after a retro-fiberglass original that had been collecting dust on a nearby shelf. Given his background as a metallurgist in industry, showcasing his skills with the gasoline tank was another opportunity to demonstrate his proficiency. The final product established a contemporary atmosphere for the design, harmonizing timeless elements with its sleek, refined dimensions, perfectly complementing the CB’s sleek profile.

Following completion of the tank design, attention shifted to conceptualizing the vehicle’s overall body. “I was drawn to the clean lines and minimalist aesthetic of cafe racers, but when it came to my own project, I struggled with the sharp angles inherent in the CB chassis – a departure from the smooth curves I had envisioned.” Jeremy notes that he fabricated a completely fresh frame aside from the neck and downtube by creating new tubing and assembling it into shape.

The all-new body is perfectly complemented by a state-of-the-art suspension system. With conversion components sourced from Cognito Moto’s extensive catalogue, the entrance design was elevated by the integration of Yamaha R1 forks and premium Cognito billet triple clamps. At the heart of this innovative design lies a CBR F2 swingarm, uniquely paired with a cutting-edge twin shock system situated within its rear. As he installed his first shock absorber, he discovered they didn’t quite deliver the extra bounce he desired. Undeterred, he added another, only to find himself enamored with the result – an unplanned yet satisfying outcome that proved a happy accident in the design process.

Plans often adapt and evolve during the development of a custom project. Being an informed builder doesn’t preclude the risk of errors, and Jeremy is always eager to improve his skills further.

“After finalizing the bodywork, I crafted the seat cowl from aluminum and seamlessly integrated the bike’s oil tank into the design,” he remarks. Despite completing the cowl, I stumbled upon Outsiders Bikes’ Sump Factor.

The SUMO Factor is a novel innovation designed specifically for Honda’s SOHC 750F and OK series engines, revolutionizing the performance dynamics of these iconic powerplants. The conversion kit is engineered to transition vehicles from a dry sump system to a wet sump configuration by employing an extension plate that effectively lowers the oil pan. Jeremy’s enthusiasm for CB radios was palpable, particularly given the significant advancements in engine design that came with this technology. After incorporating the Sump Factor, he creatively repurposed his custom-designed cowl by seamlessly integrating electrical components within its structure.

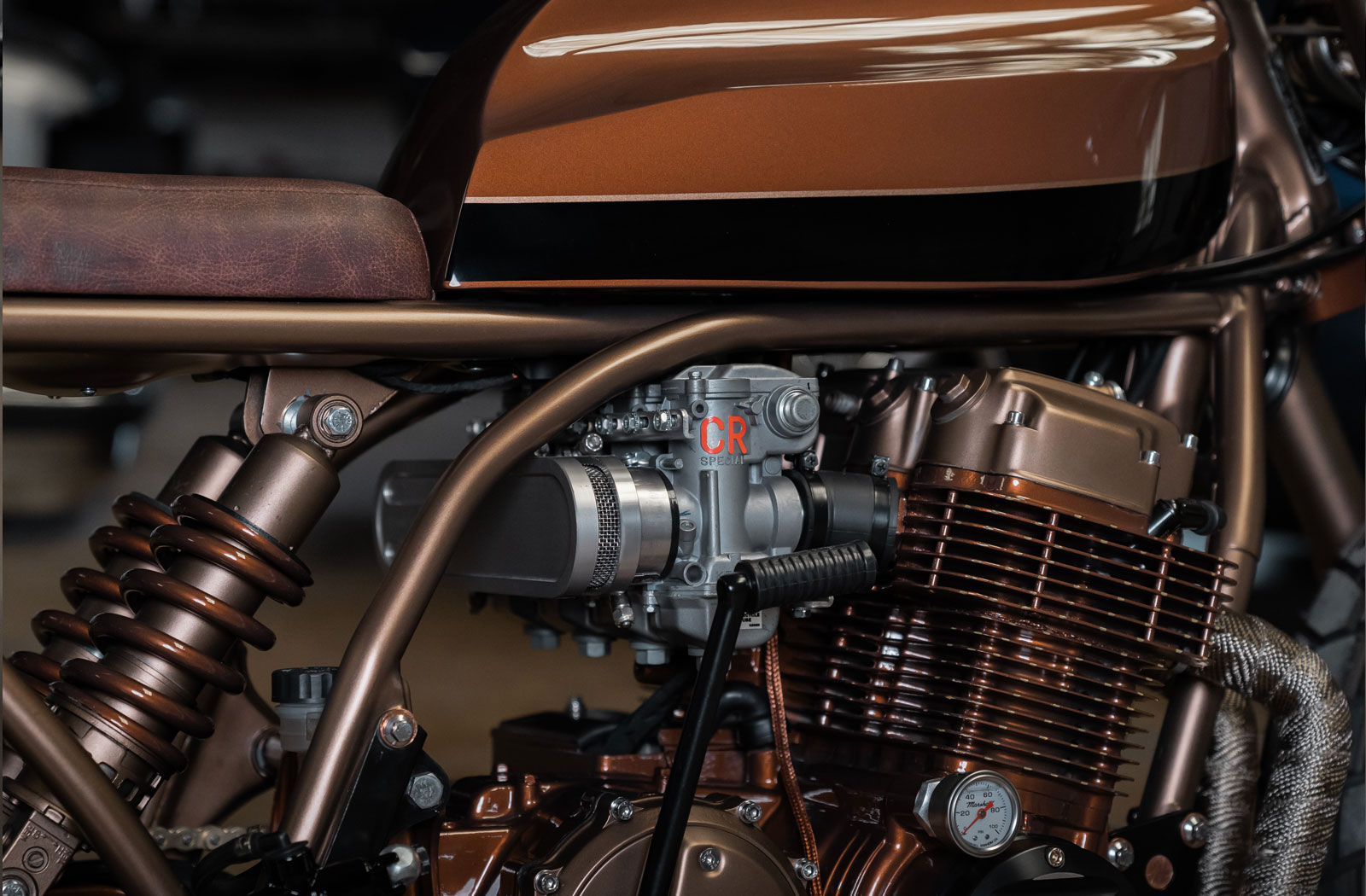

Jeremy’s primary focus was never on large-scale positive energy factors, instead opting for a simple rebuild and refresh; the only notable modification was the upgrade of consumption and exhaust systems. The inline-four engine is now equipped with a quad-CR carburetor setup, drawing in air through a high-performance Cognito Moto air filter system. Perched atop the powerplant’s rear sits a custom-built 4-into-2 exhaust system, featuring wrapped headers and sleek stainless steel megaphone-style mufflers.

During the construction process, Jeremy decided to add several modern upgrades to enhance the performance of his CB. The custom motorcycle features a selection of premium components, including electrical elements sourced from Motogadget, spoked wheels for added durability, and advanced lighting systems comprising projector LED headlamps and rear units supplied by Cognito Moto. The bike’s luxury finish is further enhanced by the addition of a sumptuous new saddle, replete with rich APEX leather trim. The vehicle’s finishing flourish comes in the form of a customised LED rear light that employs reflection technology to produce an infinity-effect illusion. The bike’s newly redesigned appearance far surpasses the impact of its upgraded components.

During the teardown process, we affectionately dubbed the bike ‘Penny’ after uncovering a few forgotten pennies beneath the saddle. With a mind set on pairing up with a copper and gold color palette, Jeremy recollects. “I commissioned a bespoke colour palette from BASF, carefully selecting and mixing two precise shades to achieve the exact hue you’re seeing before you.” I also utilized pennies as spacers beneath the ARP bolts.

With little surprise, Jeremy’s meticulously crafted CB750 cafe racer drew a crowd at the recent Handbuilt Show in Austin, Texas. Hopefully, it won’t be too long before he gets another chance to build a personal project because this one is truly exceptional in its elegance.

Pictures by Alex Sellers Media